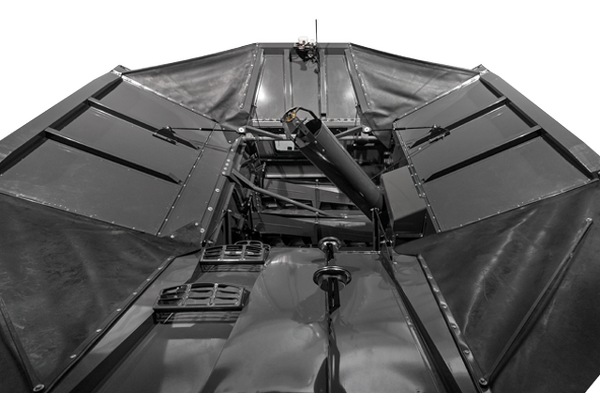

Grain tank and discharge

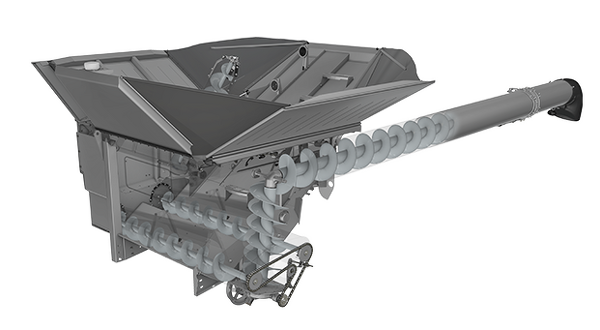

Fendt IDEAL 7 and 8 come with a choice of two-grain tank versions. The Streamer 6.0 with a 485 bushel (bu) capacity and an industry-leading 6.0 bu/sec average unload rate, or the Streamer 4.0 with 350 bu capacity and a 4.0 bu/sec average unload rate. The enormous volume and increased unloading rate do justice to the enormous output of the Fendt IDEAL. The key to the enormous speed is the huge diameter of the unloading auger. The large diameter of 19 inches with a few auger flights allows for simultaneous low speeds which guarantee high crop quality. Gently and with low power requirements, the grain tank is fully unloaded within 81 seconds.

Fewer and shorter stops for unloading are soon reflected in greater daily productivity – sensors for yield and moisture and a grain quality camera are fitted to the elevator. The data is accurate to 98% and applied with the VarioDoc ISOBUS standard, live yield mapping, and IDEALharvest™. Your harvest data is easily transferred and utilized by your choice of FMIS systems.

The clean grain elevator is designed for a throughput of up to 8000 bu./ hr. This gives enough capacity in all crop conditions, 40 convex paddles ensure maximum performance with gentle handling of the crop.

The Fendt IDEAL gives you a choice of unloader widths of 28 ft, 32.6 ft, and 36.2 ft, measured from the middle of the machine. Both the largest versions can also be folded into the transport position behind the combine. A flap is fitted to the end of the unloading auger to prevent unnecessary losses when the unloading process stops. This is automatically opened or closed by a hydraulic cylinder when the unloading process starts and stops, and therefore reliably prevents valuable crop from dribbling away. An adjustable end spout for the unloading auger is available to help fine-tune the flow of crop. This allows the operator precise placement of the crop into the grain cart or truck.