-

Products

-

Tractors

back to Overview

-

Fendt 1100 Vario MT

from 376 kW / 511 hp to 495 kW / 673 hpFendt 1000 Vario

from 376 kW / 511 hp to 495 kW / 673 hpFendt 1000 Vario Fendt 1000 Variofrom 291 kW / 396 hp to 380 kW / 517 hpFendt 900 Vario MT

Fendt 1000 Variofrom 291 kW / 396 hp to 380 kW / 517 hpFendt 900 Vario MT Fendt 900 Vario MTfrom 279 kW / 380 hp to 317 kW / 431 hpFendt 900 Vario

Fendt 900 Vario MTfrom 279 kW / 380 hp to 317 kW / 431 hpFendt 900 Vario Fendt 900 Variofrom 217 kW / 296 hp to 305 kW / 415 hpFendt 700 Vario Gen7

Fendt 900 Variofrom 217 kW / 296 hp to 305 kW / 415 hpFendt 700 Vario Gen7 Fendt 700 Vario Gen7from 149 KW / 203 hp to 223 kW / 303 hpFendt 700 Vario Gen6Fendt 700 Vario Gen6from 106 kW / 144 hp to 174 kW / 237 hp

Fendt 700 Vario Gen7from 149 KW / 203 hp to 223 kW / 303 hpFendt 700 Vario Gen6Fendt 700 Vario Gen6from 106 kW / 144 hp to 174 kW / 237 hp -

Fendt 600 Vario

Fendt 600 Variofrom 110 kW / 149 hp to 154 kW / 224 hpFendt 500 Vario

Fendt 600 Variofrom 110 kW / 149 hp to 154 kW / 224 hpFendt 500 Vario Fendt 500 Variofrom 91 kW / 124 hp to 120 kW / 163 hpFendt 300 Vario

Fendt 500 Variofrom 91 kW / 124 hp to 120 kW / 163 hpFendt 300 Vario Fendt 300 Variofrom 83 kW / 113 hp to 104 kW / 142 hpFendt 200 Vario

Fendt 300 Variofrom 83 kW / 113 hp to 104 kW / 142 hpFendt 200 Vario Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hpFendt 200 VFP Vario

Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hpFendt 200 VFP Vario Fendt 200 V/F/P Variofrom 58 kW / 79 hp to 91 kW / 124 hp

Fendt 200 V/F/P Variofrom 58 kW / 79 hp to 91 kW / 124 hp

-

- Combines

- Planters

- Sprayers

-

Tractors

The new Fendt Slicer model range of mower combinations is available in two working widths: Fendt Slicer 960 and Fendt Slicer 1010, each with conditioner. The 960 stands for a maximum working width of 9.60 meters and the 1010 for a maximum working width of 10.10 meters. Models with the suffix KC are equipped with a tine conditioner, while the RC designation refers to the roller conditioner. The Pro suffix indicates ISOBUS functions, while the B designation stands for groupers. The series includes the following butterfly mowers:

| With conditioner | Fendt Slicer 960 KC | Fendt Slicer 960 RC | Fendt Slicer 1010 KC | Fendt Slicer 1010 RC |

| With conditioner & ISOBUS | Fendt Slicer 960 KC Pro | Fendt Slicer 960 RC Pro | Fendt Slicer 1010 KC Pro | Fendt Slicer 1010 RC Pro |

| With conditioner, ISOBUS & groupers | Fendt Slicer 960 KCB Pro | Fendt Slicer 960 RCB Pro | Fendt Slicer 1010 KCB Pro | Fendt Slicer 1010 RCB Pro |

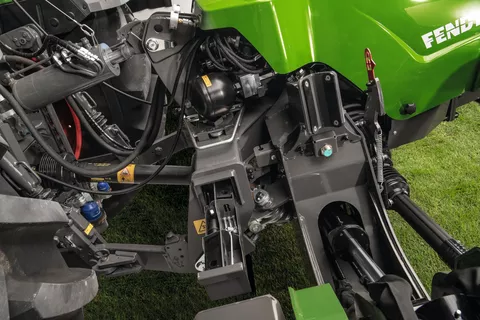

Thanks to a pendulum travel of -19° to +26°, the mower works precisely even in undulating terrain. Using two pins, the mower units are positioned 15 cm further in or out, without shortening the PTO shaft, in order to overlap optimally with the front mower unit. This allows the mower combination to be linked with various front mowers. In combination with the Fendt Slicer 960, a front mower fits with a working width of 3.10 meters. The Fendt Slicer 1010 is driven together with a front mower of 3.60 meters working width, such as the Fendt Slicer 360 FQ front mower.

A total of 12 new models replace the Fendt Slicer 9314 TLKCB and 991 TLKC models. This allows customers to choose exactly the right model to match their operation.

Spur gear cutter bar with large discs – flexible and low-wear

The Streamline spur gear cutter bar is already familiar from the Fendt Slicer 860 and 960 mower combinations, the Fendt Slicer TLX rear mowers and the Fendt Slicer F and FQ front mower models. When developing the spur gear cutter bar, the focus was on durability, high efficiency and a flat design. The robustly designed cutter bar combines high throughput with a steady flow of forage even in challenging conditions.

The drive concept, which is consistently designed for efficient use of power, allows a reduced PTO speed of 850 rpm under good conditions. The overload protection and the integrated free wheel in the gearbox prevent damage to the machine. These functions save fuel, protect components and the environment.

Floating cut due to TurboLift

Developed for a wide range of operating conditions and tested internationally, all models of the new Fendt Slicer butterfly mowers feature the TurboLift hydropneumatic cutter bar relief system and specially shaped extension arms for greater freedom of movement. The floating cut reduces the contact pressure and guides the mower precisely along the contours of the ground. With TurboLift, drivers can continuously adjust the mower directly from the cab to the conditions while driving. This protects the sward andfurtherreduces the amount of contamination in the forage and fuel consumption. In addition, the system calibrates itself again and again at the headland, thus reducing the effort for drivers.

TurboLift system with speed-dependent control

A new feature is the optional speed-dependent control of the contact pressure for particularly precise guidance for the Fendt Slicer Pro models with ISOBUS. This control supplements the familiar TurboLift hydropneumatic cutter bar relief and is oriented to the working speed. It exerts the required contact pressure at all times and regulates the mower settings particularly precisely for a clean cut, even when the working speed changes. If the working speed increases, the contact pressure also increases and the mower is guided even more precisely along the ground contours. This prevents possible bouncing due to uneven ground contours and prevents damage to the sward. If the working speed drops, for example due to dense crops, the cutter bar is relieved of more load. After entering a target value, the support pressure can be controlled in three setting levels. In the first level, the contact pressure is increased by 0.35 bar per km/h different from the entered target value, the medium level is at 0.8 bar per km/h and the high level is at 1.25 bar per km/h adjustment.

The control for speed-dependent ground pressure is available for the Fendt Slicer mower combinations and the Fendt Slicer FQ front mowers. This control also reduces the amount of crude ash in the feed, thus increasing feed quality, while at the same time reducing fuel consumption.

Tine and roller conditioner for Fendt mowers

The Fendt Slicer 960/1010 KC and KCB with tine conditioner creates an air-permeable forage structure, requires a low speed and thus operates particularly fuel-efficiently. The Fendt Slicer 960/1010 RC and RCB models are equipped with a roller conditioner. Farmers and contractors can now choose between a rubber or steel roller conditioner to better address regionally varying crops.

The roller conditioners are specially designed for gentle conditioning in leafy crops such as clover or alfalfa. The Fendt Slicer 960 and 1010 RC and RCB are equipped with the direct drive RC DUO Drive as standard. RC DUO Drive drives both rollers and achieves a high throughput even in heavy and moist crops.

Automated conditioning intensity for butterfly and front mowers

In short periods of good weather, the use of a mower with conditioner significantly shortens the wilting process. The new conditioners have already been introduced with the Fendt Slicer 860 KC and 860 RC. Now, drivers of the Fendt Slicer 960 KC Pro and 1010 KC Pro models with tine conditioner, as well as those with conveyor belt, can also control the intensity of the conditioning variably and directly from the cab. As an added convenience, the counter-comb adjustment can be done automatically either with the help of a sensor or through the use of satellite data and the application maps derived from it. Via the ISOBUS function, the rear mower also controls the conditioning intensity in the front mower, such as the Fendt Slicer FQ. The three mower units can react individually to different conditions across the entire working width. Thus, the intensity of the conditioning of the front mower can differ from that of the rear mower units, just as the intensity of the two rear mower units can be regulated differently.

If the sensor is used, it detects the biomass in real time. With the help of the sensor data, a linear motor continuously controls the intensity of the conditioning. When used with satellite-based application maps, the conditioner accesses the data from the transmitted biomass. The goal: a more homogeneous drying of the forage for a higher forage quality. Due to the more homogeneous drying, the forage reaches the desired dry matter content at a uniform time. This leads to a uniform and high basic forage quality and is decisive for economically successful dairy cattle feeding.

Newly designed groupers for flexible swath widths

Mowers with groupers are usually used in combination with powerful forage harvesters or forage wagons. If the rouper moves the material more cleanly, the throughput of the forage harvester or forage wagon increases. The grouper belt of the Fendt Slicer series has been further developed precisely for this process and enables more flexible swath widths with the familiar BeMove function. Drivers use BeMove to continuously adjust the swath width and the working speed of the conveyor belts. With the aid of this function, swath widths of 1.60 m – 3.00 m are possible, which fit exactly to the working width of the following machines.

The new robust hydraulic motor drives a drive roller with an increased diameter, so the conveyor belt can work faster than before. The swath width decreases thanks to the higher working speed. If a forage wagon is used for retrieval, this is optimal. Alternatively, the groupers can be used to create swaths or place the material close to the field boundaries. In this way, a larger working width can be realised with the rake and the driver of the rake can cover a greater area.

The grouper belts are now at a flatter angle to the mower unit. Due to the new working position, they are fed more evenly across the entire belt width. This optimises the forage transport. Newly developed two-part plastic bars provide aggressive forage collection, increasing overall performance. An edge protector on the rear wall facilitates cleaning, avoids forage accumulation on the belt and also ensures even feeding. In addition, a frame prevents dirt from entering the space in between, and wipers on the outer sides further facilitate cleaning.

New angle sensors detect the position of the conveyor belts and balance them according to the machine's centre of gravity. Especially if you initially mowed with the belt, but in the following operation the belt is folded up, BeMove automatically shifts the belt for optimal balance.

Automatic lateral shift for Fendt Slicer mowers

If the front and rear mowers are not optimally matched, strips can easily be left, especially when mowing on slopes or in curves. These either remain on the area or have to be mowed again in another pass. In order to prevent this strip formation, Fendt has developed an automatic lateral shift for the Fendt Slicer front mower, controlled by the rear mower.

Automatic lateral shift is available for the Fendt Slicer FQ in conjunction with a new ISOBUS-enabled Fendt Slicer model. The control is based on the data from the rear mower and automatically shifts the front mower. To do this, sensors detect the angle of inclination of the rear mower and the steering angle of the tractor. Based on this information, the front mower is shifted laterally by up to 20 cm at a time. This ensures sufficient overlap and eliminates the need for manual shifting. The automatic lateral shifting prevents missing areas as well as driving over the standing crop and relieves the driver even at a higher working speed. In addition, double passes due to re-mowing are eliminated. This corresponds to a time saving of about ten percent and saves fuel. Another advantage: less contamination gets into the forage. These factors also reduce the cost per hectare and protect the soil. When reversing, the mower raises automatically. This prevents driving errors and further relieves the driver. After work, the front mower is automatically centred for road transport and thus meets all legal requirements.

Section Control for mower combinations

Section Control is optionally available for the Fendt Slicer Pro. Section Control detects the areas being worked and automatically raises the mower as soon as areas that have already been worked, such as the headland, are passed over. This reduces dirt ingress and wear, relieves drivers and increases efficiency.

All Fendt Slicer models are equipped with a triple hectare counter. This allows contractors to automatically record the area output of up to three customers in parallel. The function reduces the documentation effort and facilitates billing.

Quick and easy maintenance of the mowers

The design and construction of the mowers are built for durability as well as easy and quick maintenance. The intelligent design of the overall structure significantly reduces dirt accumulation. If necessary, the mower can be blown out quickly and easily. The new hose cabinet is located under the bonnet and all hoses are stowed away protected from the weather. Indicators for the working height and the transport lock are visible directly from the tractor cab. In addition, there is a chain to indicate the transport height. Features such as automatically folding light carriers and ergonomically easy-to-reach lubrication points, as well as a lubrication bar for all harder-to-reach lubrication points, make maintenance easier.

The safety guard of the Fendt Slicer 960/1010 can be optionally hydraulically and thus conveniently folded from of the tractor cab. This considerably shortens the set-up time in the field. Drivers can lock the front guard in different positions with the help of a lever. This facilitates both access to the cutter bar for fast blade changes and making maintenance work easy.

All butterfly mowers are equipped with a tool box and a quick-change blade tool as standard. The tool independently holds the mowing disc in the open position so that the blade can be changed with both hands. This increases work safety and comfort.

Safety in the field and in mower transport

The Fendt Slicer 960 and 1010 butterfly mowers are also designed for professional use in terms of safety precautions. This means that the mower's drive train is protected up to 2,100 Nm and thus also for high throughput with large tractors.

An additional optional support wheel for road transport reduces the axle load by shifting it from the tractor to the support wheel and increases driving comfort when driving on roads. The support wheel can be folded hydraulically directly from the cab.

An optional LED headlamp package ensures work safety even in low-light conditions. The headlamps optimally illuminate all important working areas, even in the dark. Customers can choose between five and seven headlamps, depending on the model.

The patented Fendt SafetySwing mechanical collision safety system prevents damage caused by poorly visible manhole covers, tree stumps or large stones. If the mower unit collides with an obstacle, the sensor-monitored collision protection is triggered. In the process, the mower units swing upwards independently of each other and thus lift over the obstacle. The large lever arm reduces possible damage to the mower unit. The mower units then fold back into the working position so that work can continue. If Fendt SafetySwing is triggered, a message appears directly in the tractor terminal so that drivers can check the mower unit for damage.

The new models of the Fendt Slicer 960 and 1010 butterfly mowers will be available to order from Summer 2024.

Innovations for mowers of the Fendt Slicer series

The direction of travel of the mower discs determines the shape, width and height of the swath. To facilitate subsequent work, the running direction of the mower discs for special models will be changed from half-pair to central running with immediate effect. This adjustment applies to the following models:

- Fendt Slicer F/F KC/F RC

- Fendt Slicer FQ/FQ KC/ FQ RC

- Fendt Slicer TLXKC/TLXRC

- Fendt Slicer 860 KC/860 RC

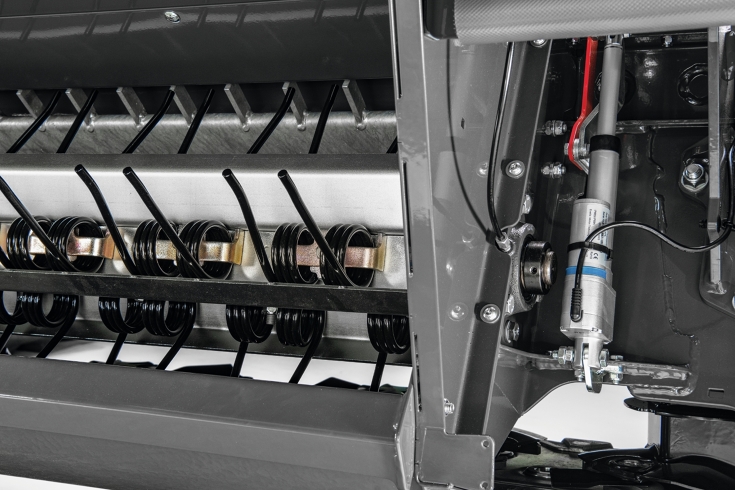

New design of the shearbar

The shearbar of the new cutter bar has been revised and now has an anvil. In addition, the spring for quick-change blade is now equipped with scrapers. These keep the spacing between the disc and the shearbar small and thus clean. The combination of anvil and scrapers ensure an even cleaner and more uniform cut.

This innovation is available as standard for all Fendt Slicer models from September 2023. Existing machines can be equipped with the new shearbar via a field kit.