Precision work with maximum comfort

Maximum operating comfort, savings on operating resources and reduced stress on the driver increase the quality of work. This is exactly where machine control with Fendt comes into play. This allows you to work even more precisely and comfortably, because the exact application rate of operating resources can be controlled with pinpoint accuracy using an intuitive operating system.

The problem: chaos in the tractor cab

In the past, each manufacturer relied on its own electronic solutions, which meant that special adaptations were required for each combination of tractor and implement. The result is a patchwork of different terminals, control boxes and external joysticks, along with a tangle of cables in the cab. Monitoring the quality of work from the cab and safety when manoeuvring the tractor-implement combination is restricted.

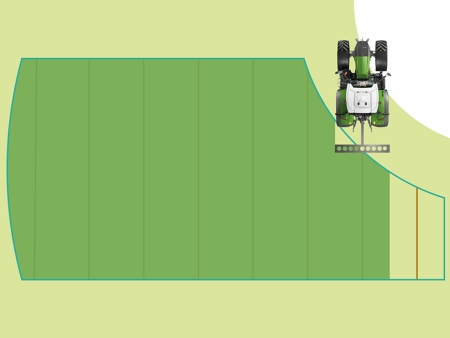

The solution: ISOBUS eliminates isolated solutions

ISOBUS eliminates isolated solutions and provides a standardised interface between the tractor and the implement that works via “plug and play”: simply plug the ISOBUS connector into the ISOBUS socket and the operating screen of the implement is displayed on the terminal.

To ensure that this works smoothly, the AEF monitors the ISOBUS standard on the ISO11783 norm across all manufacturers. The ISOBUS functionalities must be supported by the tractor-implement combination for communication between the two to work optimally.

To ensure that this works smoothly, the AEF monitors the ISOBUS standard on the ISO11783 norm across all manufacturers. The ISOBUS functionalities must be supported by the tractor-implement combination for communication between the two to work optimally.

AEF ISOBUS database

The AEF ISOBUS database is a valuable reference regarding the ISOBUS functions supported by machines and their compatibility with products from other manufacturers. This gives you access to the relevant information before purchasing so you can choose an ISOBUS combination that is tailored to your needs.

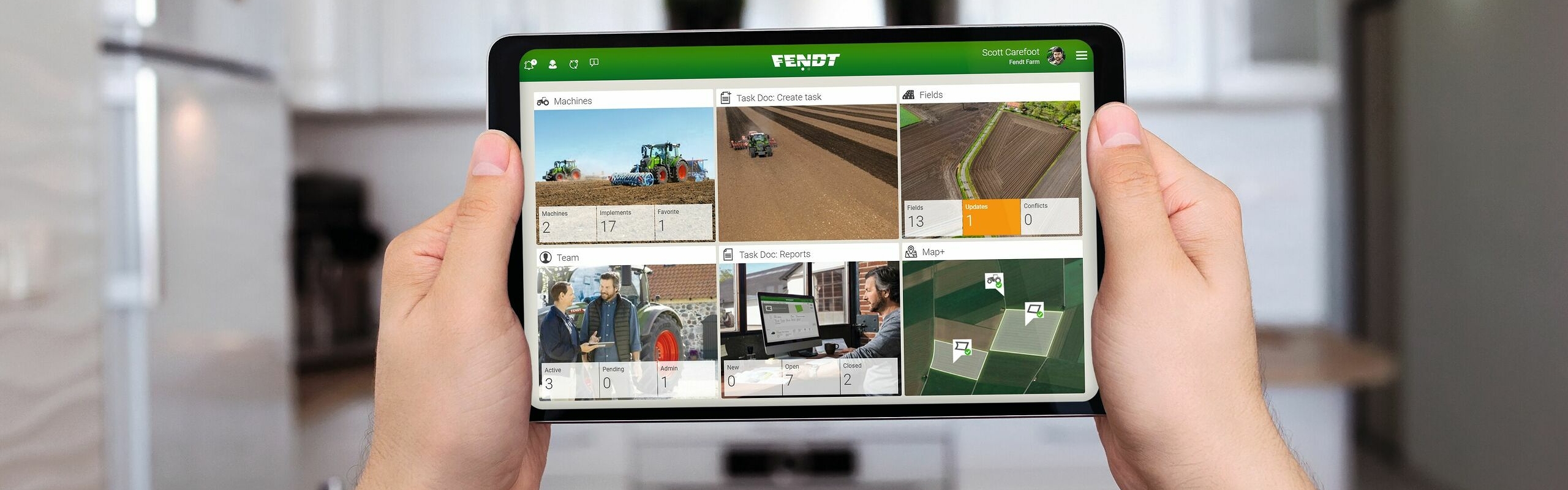

Discover the functions of FendtONE offboard that support you when it comes to machine control.

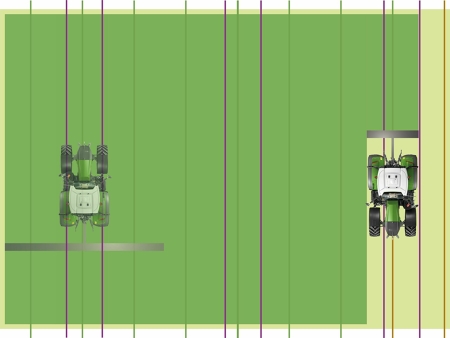

Machine control and Task Doc task reports

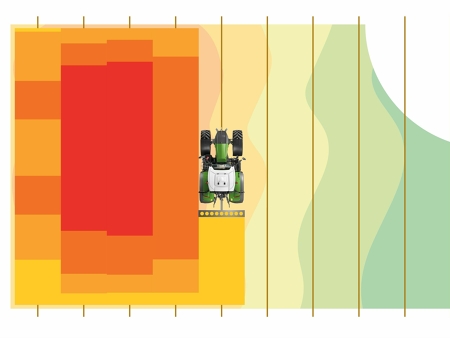

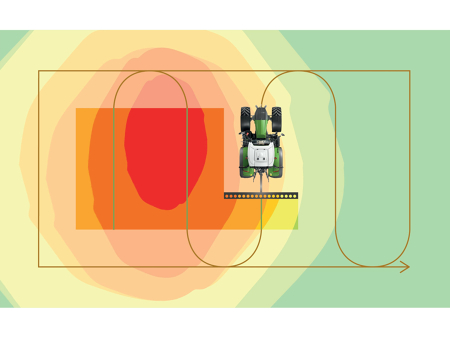

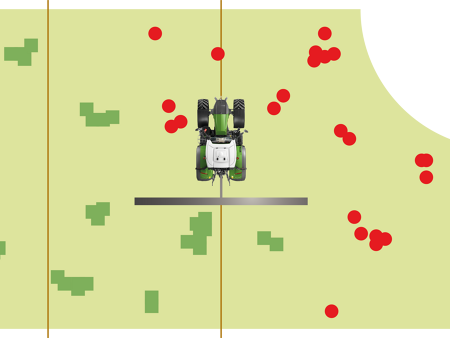

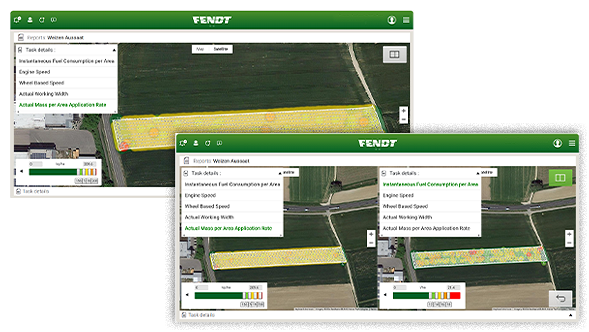

Visualisation of machine parameters in heat maps of task reports

When the tractor and implement were used in the field, data worthy of documentation was already provided when the machine/device combination was set up. For ISOBUS implements, the values of standardised parameters are documented at regular intervals together with the GPS position during field work. This is important information for the documentation and forms the basis for later decisions.

FendtONE offboard is the ideal solution for this:

- Clearly view total values in the task report and use them as a basis for documentation or billing

- Visualisation of ISOBUS parameters and tractor key figures in heat maps

- Comparison of two parameters or key figures next to each other in heat maps