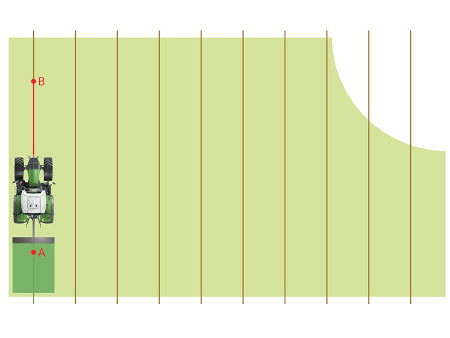

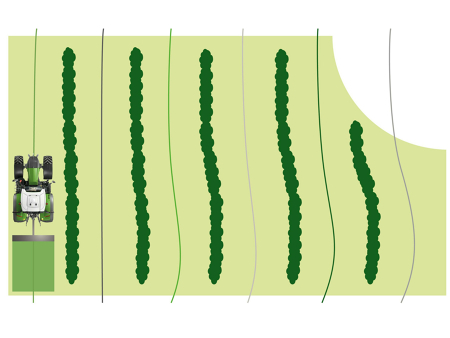

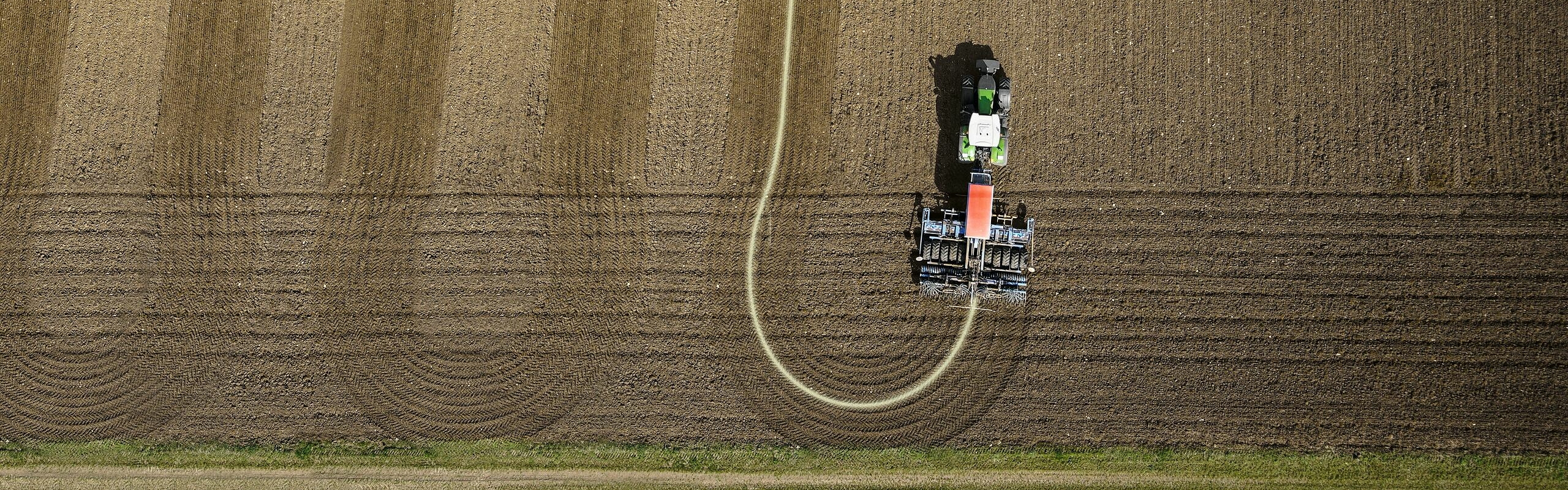

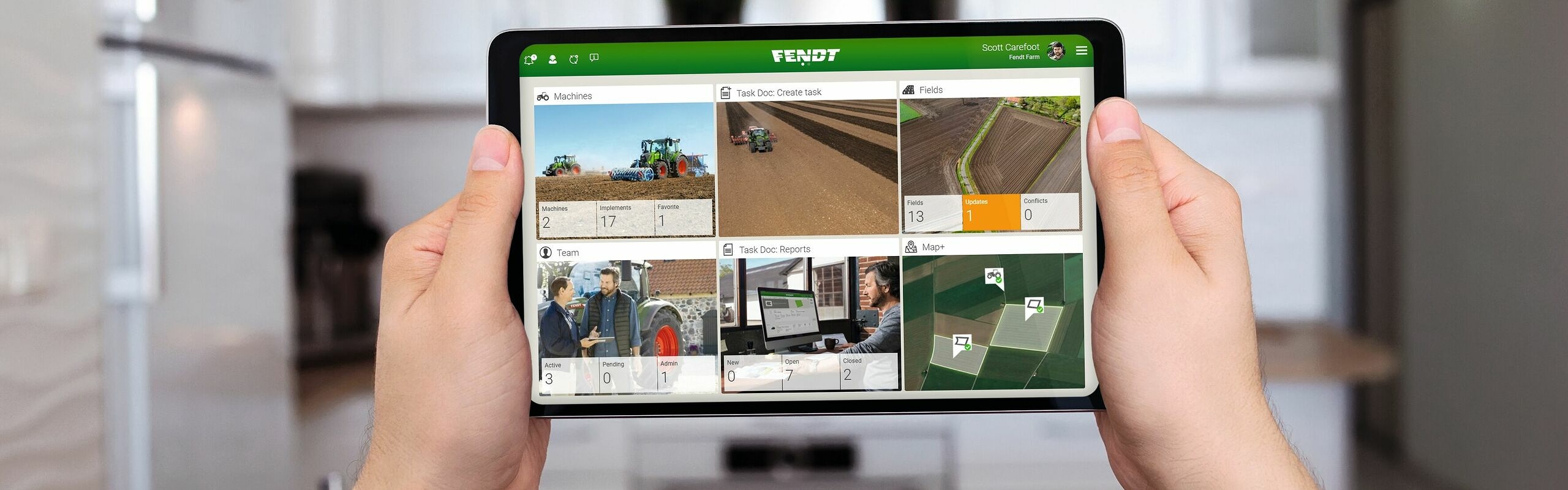

Efficient working by relieving the driver

Precision work is the perfect solution for reducing operating costs and saving time. Especially on long working days, this requires the highest concentration and attention from the driver. Fendt's guidance system provides support exactly where it's needed: the guidance system keeps the machine perfectly on the desired track, so that the driver can fully focus on the implement. Precise work with simultaneous driver relief.

Precise – but how?

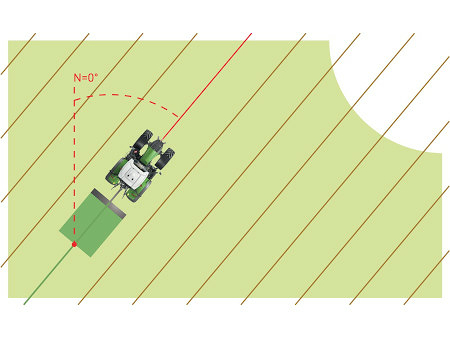

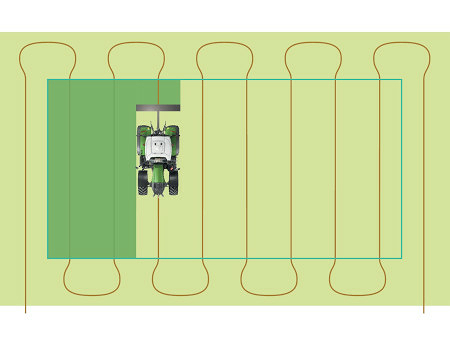

Positioning with GPS and receiver

For guidance applications in agriculture, the machine is equipped with a satellite receiver. Once the receiver has a clear view of at least three satellites, the position can be determined. Due to several interrupting factors, such as orbit errors, weather-related influences, as well as absorption and reflection in the atmosphere, GNSS (GPS) position data alone can lead to deviations of up to +/- 12 metres – too inaccurate for agricultural use. For standard applications in agriculture, such as tillage, the DGPS correction method can increase the positional accuracy of a GPS receiver to +/- 15 to 30 centimetres.

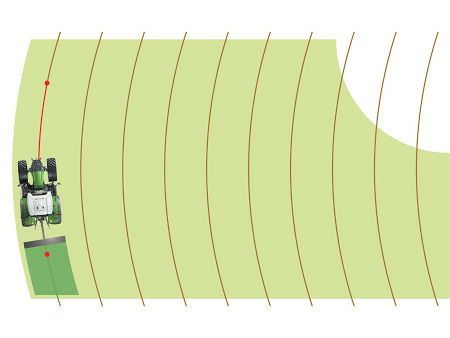

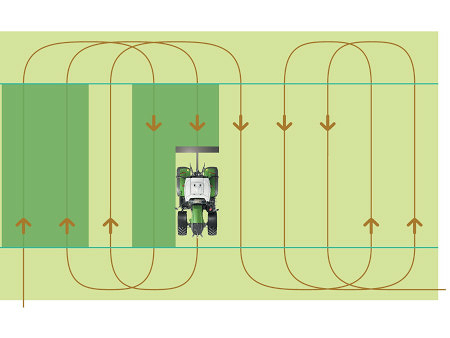

Perfection with the help of Real Time Kinematic (RTK)

For demanding, precise agricultural work in the centimetre range, correction data is not transmitted via satellite, but by radio or mobile phone. RTK (Real Time Kinematic) is the most accurate correction signal and meets the highest demands. The accuracy of RTK makes it possible to maintain field data cleanly and to use it again and again for follow-up work or in later years. In addition, RTK is recommended for all measures that require the utmost care, such as activities involving the application of operating resources (e.g., sowing).

+/- 2 cm

Pass-to-pass accuracy

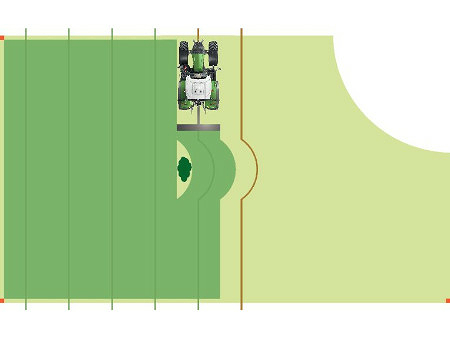

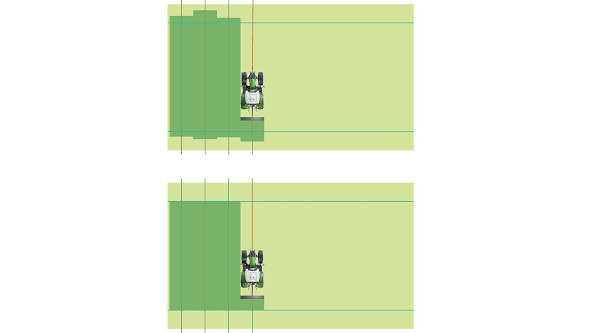

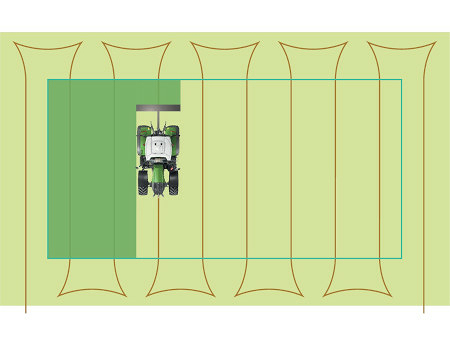

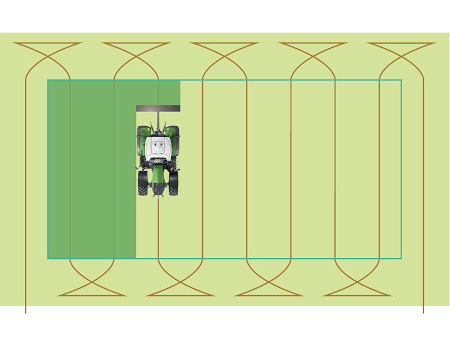

Implement Slope Compensation – precise work in hilly terrain

When working on slopes, semi-mounted implements can drift due to their own weight, resulting in passes not matching up. To counteract the drift on a slope, manual intervention in the guidance is the only way to correct the course.

With the slope compensation function, the driver can now specify a slope compensation, which sets a correction value. The tractor corrects its course quite automatically so that the implement works its tracks cleanly. This means that manual countermeasures are not necessary – increasing both working comfort and accuracy!

With the slope compensation function, the driver can now specify a slope compensation, which sets a correction value. The tractor corrects its course quite automatically so that the implement works its tracks cleanly. This means that manual countermeasures are not necessary – increasing both working comfort and accuracy!