Might and variety are highlighted here.

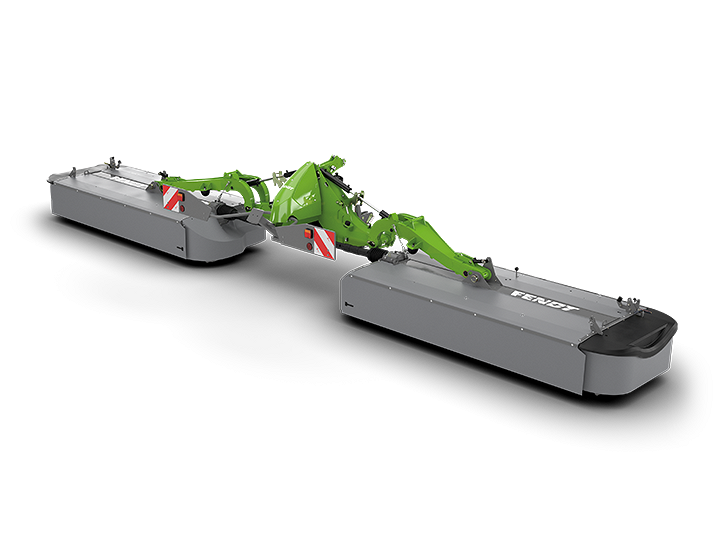

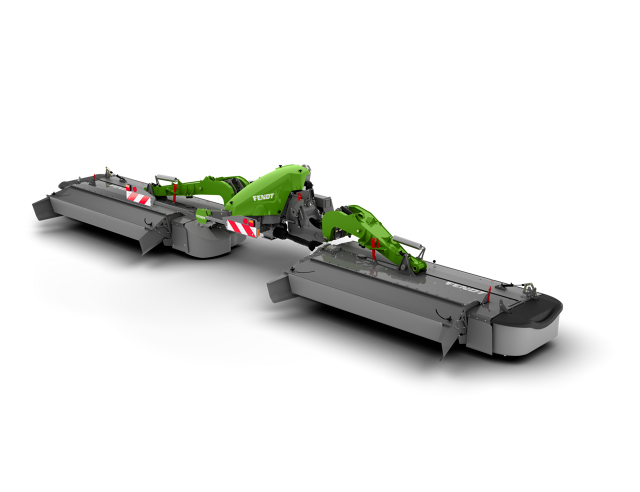

With a total of 16 different models, Fendt offers an enormous variety of rear mower combinations. Starting from the light models for smaller operations to the highly technical models with the most innovative DLG award-winning technology for contracting and larger operations.

Model overview

Without conditioner

Working width | Number of cutting discs | |

| Slicer 860 | 8,30 / 8,60 m | 2 x 6 |

| Slicer 960 | 9,30 / 9,60 m | 2 x 7 |

With conditioner

Slicer 860 KC / RC | 8,30 / 8,60 m | 2 x 6 |

Slicer 960 KC / RC | 9,30 / 9,60 m | 2 x 7 |

Slicer 1010 KC / RC | 9,80 / 10,10 m | 2 x7 |

With conditioner & ISOBUS

Slicer 960 KC Pro / RC Pro | 9,30 / 9,60 m | 2 x 7 |

Slicer 1010 KC Pro / RC Pro | 9,80 / 10,10 m | 2 x 7 |

With conditioner, ISOBUS & groupers

Slicer 960 KCB Pro / RCB Pro | 9,30 / 9,60 m | 2 x 7 |

Slicer 1010 KCB Pro / RCB Pro | 9,80 / 10,10 m | 2 x 7 |

That's how you achieve good fodder.

In this series of lightweight slicer mower combinations, the advantages of the weight-optimised construction with the most modern Fendt drive technology, high power and efficiency are combined. The efficient power transfer of the drive concept enables fuel-saving mowing with a reduced speed of 850 rpm and also the use of tractors with lower HP numbers.

Compact Transport

The low pivot point of the lifting arms result in a low centre of gravity for the mower and thus ensure greater transport safety. Despite a working width of 9.60 m, the mower units remain below the legally permissible transport height of 4.00 metres.

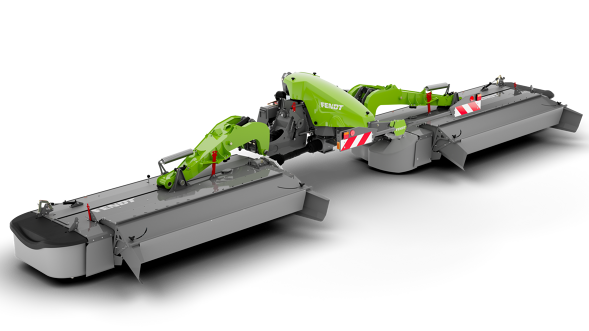

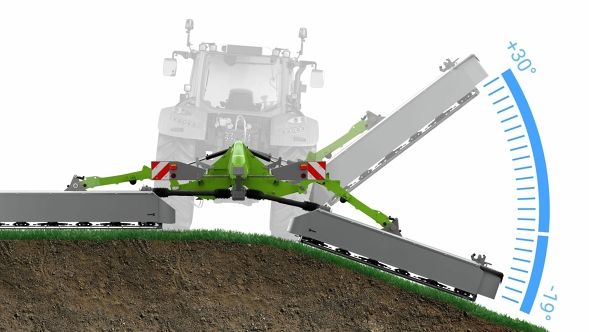

Suspension for better ground adjustment

The towed mower units are suspended centrally in the centre of gravity. This ensures excellent trailing, optimal ground tracking and prevents the cutter bar getting stuck in the ground. In combination with the curved-form extension arm, the mowing units achieve a pendulum travel of +30° to -19° and effects the compensation of unevenness and height differences. The integrated compensation cylinder prevents rocking on the headland.

Excellence and comfort in high season.

The slicer mower combinations of the newest conditioner series Fendt Slicer 960/1010 have been redeveloped from scratch to meet the increasing demands of ever shorter stable weather periods and offer contractors and large farms a wide choice. From the entry-level model Fendt Slicer 960 KC / RC without ISOBUS with 9.60 m working width to the hectare hero Fendt Slicer 1010 KCB / RCB with 10.10 m working width and the Fendt Factor with the most innovative Smart Farming technology.

More space with more comfort.

Variety with and without ISOBUS and conveyor belt

The new generation of Fendt Slicer mower combinations with conditioners are available in two working widths and three equipment versions. All models have a number of impressive and comfortable features in common. Discover the different Fendt Slicer large area mowing units for your forage harvest now.

Smart Farming mowing units with the Fendt Factor

Innovation with Power

Fendt stands for innovation and constantly setting new standards in harvest quality, productivity and ground coverage – also in green forage harvesting technology. The newest Fendt Slicer 960/1010 PRO conditioner models impress with the unique ISOBUS technology to enable more efficient harvesting, homogeneous ground fodder and higher power. Thus large quantities of high quality ground fodder is available to the farmers and their valuable livestock in narrow harvest windows - that’ the green fodder technology with the Fendt Factor.

DLG award-winning, automatic adjustment of the conditioner intensity

Grassland and forage stands show a high heterogeneous biomass growth when cut, which leads to different initial dry masses and drying speeds.

The aim is to have a consistent dry matter content of 30 to 40% across the entire field.

The Fendt Slicer 960/1010 Pro models with optional tine conditioner offer variable adjustment of the conditioner intensity thanks to the innovative ISOBUS control.

The aim is to have a consistent dry matter content of 30 to 40% across the entire field.

The Fendt Slicer 960/1010 Pro models with optional tine conditioner offer variable adjustment of the conditioner intensity thanks to the innovative ISOBUS control.

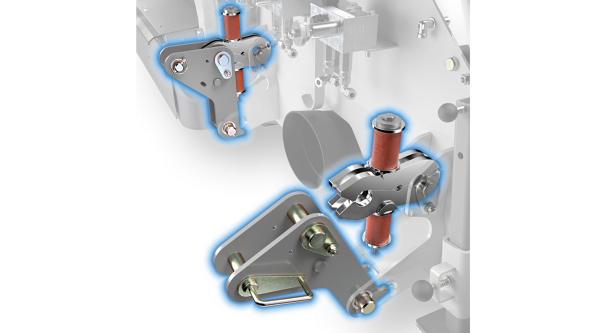

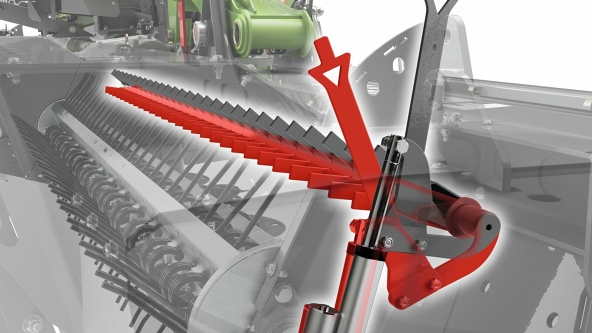

Speed-dependent TurboLift system

The hydropneumatic cutter bar relief provides for optimal contact pressure through the floating cut. The Fendt Slicer 960/1010 Pro models go beyond the pure control of the contact pressure. It permanently controls it depending on speed and constantly applies the required contact pressure at every working speed. The system works very precisely even in changing working speeds and the intensity can be adjusted to the conditions on three levels. The intelligent rear mounted mower also automatically adapts the contact pressure of comparably equipped FQ front mower.

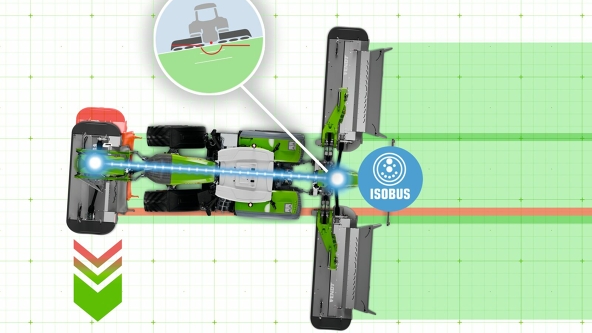

Setting the tone

With mower combinations with ISOBUS, the optional TIM allows for steering of the tractor by the rear mower. The lower links are controlled back and front on the headland and when transitioning into transport position. In addition, the TIM also controls the ISOBUS function of the FQ font mower.

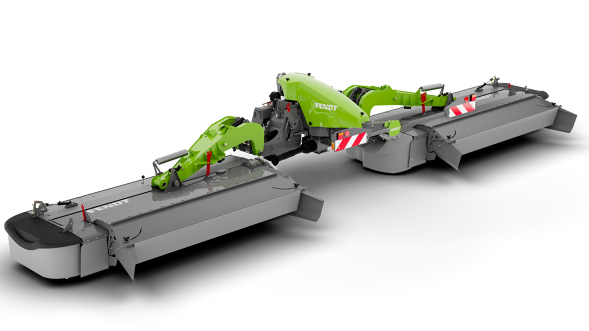

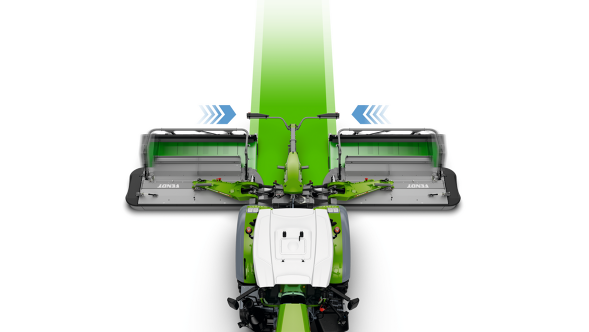

High throughput and adaptability thanks to conveyor belt and BeMove

The new Fendt Slicer belt mowers offer the highest throughput and are designed for moderate stocks, high working speeds and powerful trailed machines. The deep conveyor belts with infinitely adjustable speeds have their own oil supply that is simultaneously cooled by the grass ejection. The use of these rear mowers ensures the highest flexibility when depositing the harvest.

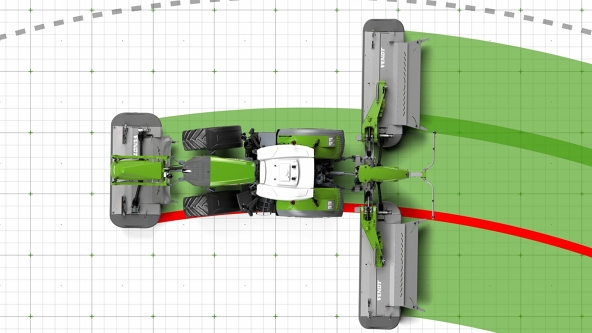

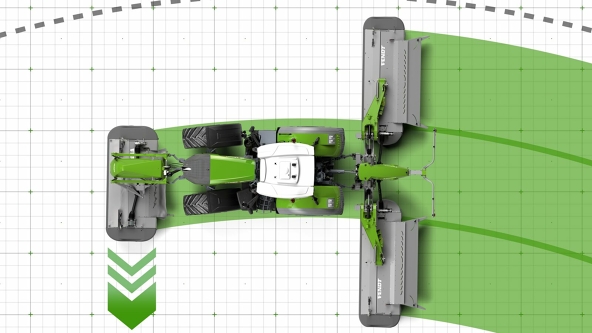

BeMove, for the perfect swath

BeMove, the hydraulic side shifting of the conveyor belts by 60 cm, enables swath widths from 1.80 m to 2.80 m in combination with the adjustable belt speed. This increases the efficiency even in the mowing process, because the swath can be rapidly adjusted to the requirements of the, possibly changing, trailing pick-up machine. The professional function of BeMove forms the perfect completed swath on the headland using automatic inward shifting of both belts. A constant swath line is ensured even on slopes and when cornering. The shift of the conveyor belts occurs on slopes depending on the slope sensor, when cornering, through the steering angle of the tractor.