The similarity of the front side of Fendt Tigo with a trough has a very specific reason. The operator always has a perfect view in the loading space through the forward sloping body design. With a loading capacity of 31 m³ to 50 m³ (DIN) you can transport your harvested crop quickly and efficiently. At 50 m³ (DIN), the Tigo MR 100 Profi really plays out this strength, as a loading wagon specially designed for hay.

Fendt Tigo: Defies anything

Fendt Tigo MR Profi.

Stay on top of things

Fast loading – Tigo MS and MR

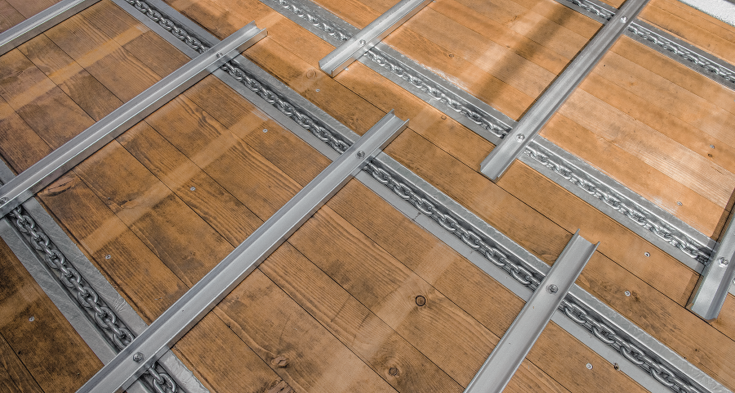

The Tigo MS and MR support you as you need it. Both models are available with or without automatic loading. With the two 2-stage automatic loading systems you can work with two different compressions. Gentle compression is applied using a bar, while moderate compression is applied by the entire loading flap. The feed is pushed from the bottom to the very top. When the entire loading space is full, the bar or tailgate presses upwards and automatically sets the scraper floor in motion for a short time, which pushes the forage back. The control unit gives you an acoustic signal when the wagon is full. This not only takes the strain off you, but ensures that the wagon is filled to optimum capacity.

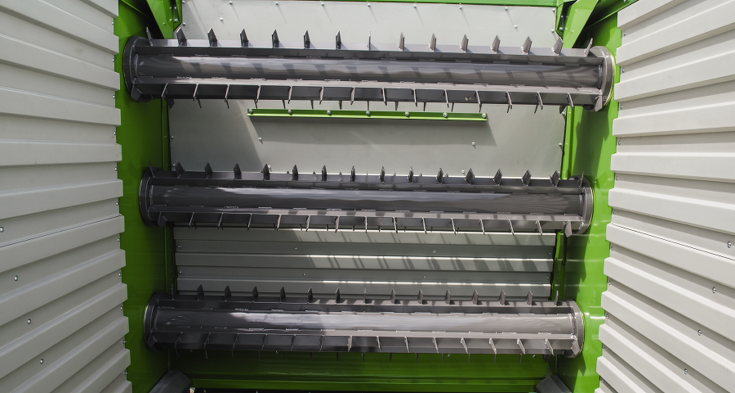

The right distribution

A consistent crop output while unloading improves the performance while compacting in the silo. You can create a uniform blanket of feed on the silo with the high-performance profile of the closed feed rollers. Grass, maize or even whole plant silage are meticulously separated from the feed stock. The Fendt Tigo ensures such a precise unloading process. In order to keep the system streamlined, the drive train shafts are enclosed in the frame. The simple design of the rollers at the rear offers you the flexibility of additional 2 m³ more loading space.