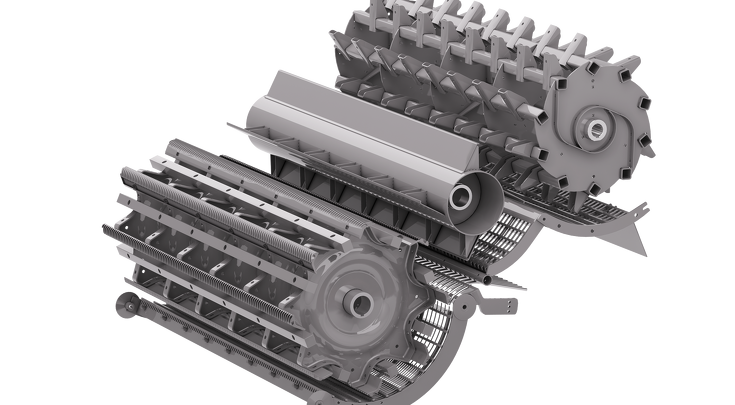

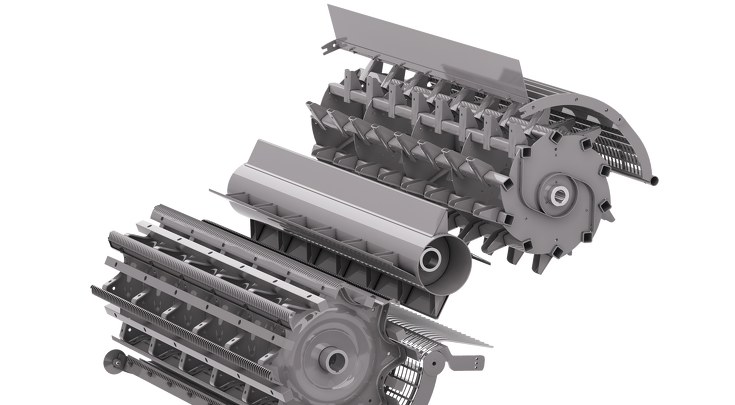

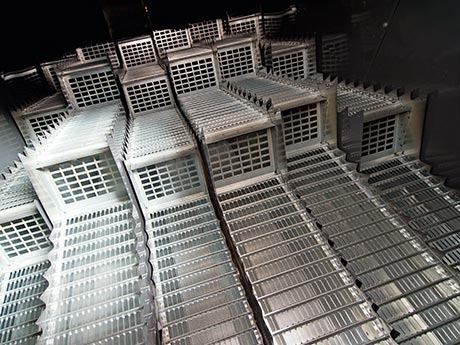

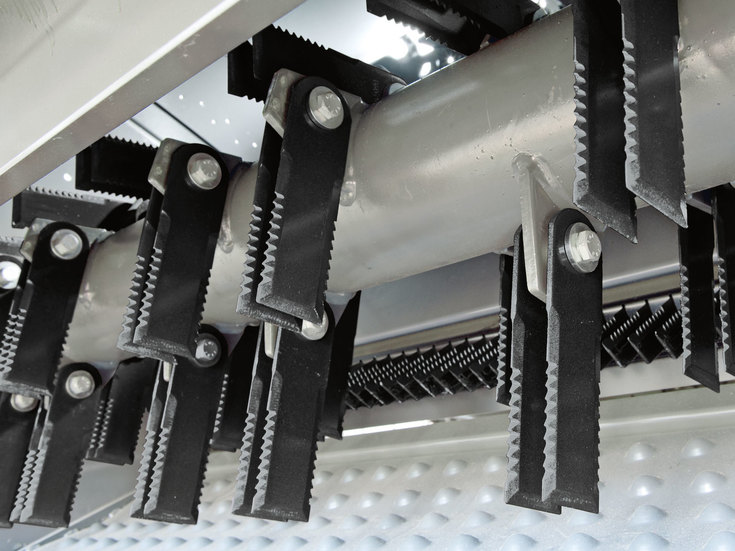

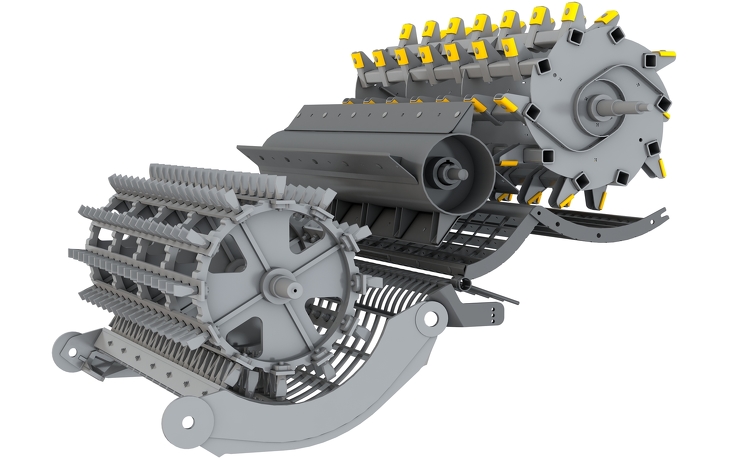

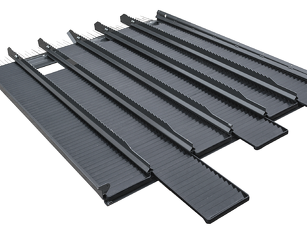

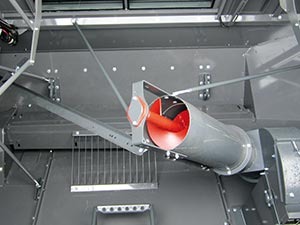

The quality of the grain determines your profit. When developing the shaker shoe, the focus was therefore on the use of high-capacity sieves to harvest the cleanest grain. The special surface of the high-capacity sieves (HC sieves) enables optimised wind flow and the highest cleaning performance. To ensure that the crop remains uniformly distributed on the sieves even on slopes, high partitions are attached to the upper sieve. The returns system transports the material that has not been optimally threshed back to the threshing cylinder. This is done very gently and evenly, because an auger above the cylinder distributes the material over the full width of the threshing unit.

Large grain tank emptied quickly:

The grain tank has a large filling capacity, 9,000 l in the standard version and 8,600 l in the ParaLevel version. The unloading speed of 105 l/sec is one of the highest in this class. From the platform, you have easy access to the grain for sampling. For additional quality control, you also have a large window in the Skyline cab that looks directly into the grain tank.