-

Products & Solutions

-

Agricultural Machinery

back to Overview

-

Tractors

-

Fendt 1100 Vario MT

from 376 kW / 511 hp to 495 kW / 673 hp

from 376 kW / 511 hp to 495 kW / 673 hp -

Fendt 1000 Vario

Fendt 1000 Variofrom 291 kW / 396 hp to 380 kW / 517 hp

Fendt 1000 Variofrom 291 kW / 396 hp to 380 kW / 517 hp -

Fendt 900 Vario MT

Fendt 900 Vario MTfrom 279 kW / 380 hp to 317 kW / 431 hp

Fendt 900 Vario MTfrom 279 kW / 380 hp to 317 kW / 431 hp -

Fendt 900 Vario

Fendt 900 Variofrom 217 kW / 296 hp to 305 kW / 415 hp

Fendt 900 Variofrom 217 kW / 296 hp to 305 kW / 415 hp -

Fendt 700 Vario Gen7

Fendt 700 Vario Gen7from 149 KW / 203 hp to 223 kW / 303 hp

Fendt 700 Vario Gen7from 149 KW / 203 hp to 223 kW / 303 hp -

Fendt 700 Vario Gen6

Fendt 700 Vario Gen6from 106 kW / 144 hp to 174 kW / 237 hp

Fendt 700 Vario Gen6from 106 kW / 144 hp to 174 kW / 237 hp -

Fendt 600 Vario

Fendt 600 Variofrom 110 kW / 149 hp to 154 kW / 224 hp

Fendt 600 Variofrom 110 kW / 149 hp to 154 kW / 224 hp -

Fendt 500 Vario

Fendt 500 Variofrom 91 kW / 124 hp to 120 kW / 163 hp

Fendt 500 Variofrom 91 kW / 124 hp to 120 kW / 163 hp -

Fendt 300 Vario

Fendt 300 Variofrom 83 kW / 113 hp to 104 kW / 142 hp

Fendt 300 Variofrom 83 kW / 113 hp to 104 kW / 142 hp -

Fendt 200 Vario

Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hp

Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hp -

Fendt 200 VFP Vario

Fendt 200 V/F/P Variofrom 58 kW / 79 hp to 91 kW / 124 hp

Fendt 200 V/F/P Variofrom 58 kW / 79 hp to 91 kW / 124 hp -

Fendt e100 Vario

Fendt e100 V Vario55 kW / 75 hp

Fendt e100 V Vario55 kW / 75 hp

-

Fendt 1100 Vario MT

-

Telehandler

-

Fendt Cargo T955

Fendt Cargo T955123 kW / 171 hp

Fendt Cargo T955123 kW / 171 hp -

Fendt Cargo T740

Fendt Cargo T740100 kW / 136 hp

Fendt Cargo T740100 kW / 136 hp

Combines-

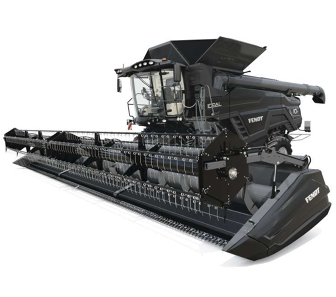

Fendt IDEAL

Fendt IDEALfrom 336 kW / 451 hp to 581 kW / 790 hp

Fendt IDEALfrom 336 kW / 451 hp to 581 kW / 790 hp -

Fendt C-Series

Fendt C-Seriefrom 225 kW / 306 hp to 265 kW / 360 hp

Fendt C-Seriefrom 225 kW / 306 hp to 265 kW / 360 hp -

Fendt L-Series

Fendt L-Seriefrom 192 kW / 260 hp to 225 kW / 306 hp

Fendt L-Seriefrom 192 kW / 260 hp to 225 kW / 306 hp -

Fendt CORUS 500

Fendt CORUS 500from 136 kW / 185 hp to 192 kW / 260 hp

Fendt CORUS 500from 136 kW / 185 hp to 192 kW / 260 hp

-

Fendt Cargo T955

-

Mowers

-

Fendt Slicer disc mowers

Fendt Slicer disc mowers

Fendt Slicer disc mowers -

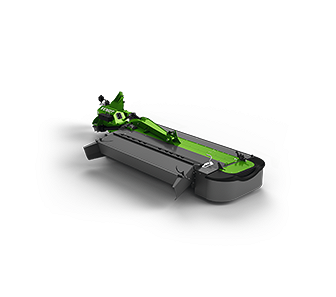

Fendt Slicer front mounted mower

Fendt Slicer front mounted mower

Fendt Slicer front mounted mower -

Rear mounted Fendt Slicer

Rear mounted Fendt Slicer

Rear mounted Fendt Slicer -

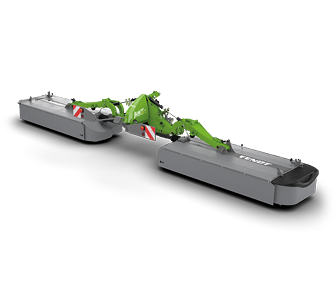

Fendt Slicer mower combinations

Fendt Slicer mower combinations

Fendt Slicer mower combinations -

Fendt Cutter

Fendt Cutter

Fendt Cutter

Forage wagons-

Fendt Tigo XR/VR/PR

Fendt Tigo

Fendt Tigo

XR/VR/PR -

Fendt Tigo MS/MR/MR Profi

Fendt Tigo

Fendt Tigo

MS/MR/MR Profi

-

Fendt Slicer disc mowers

-

Balers

-

Square Balers

Fendt Square balers

Fendt Square balers -

Rotana F

Fendt Rotana F

Fendt Rotana F -

Rotana V

Fendt Rotana V

Fendt Rotana V -

Rollector

Fendt Rollector

Fendt Rollector

-

Square Balers

-

- Areas of Application

- Smart Farming

- Original accessories & Technologies

-

Agricultural Machinery

Fendt Former C two-rotor central delivery rake

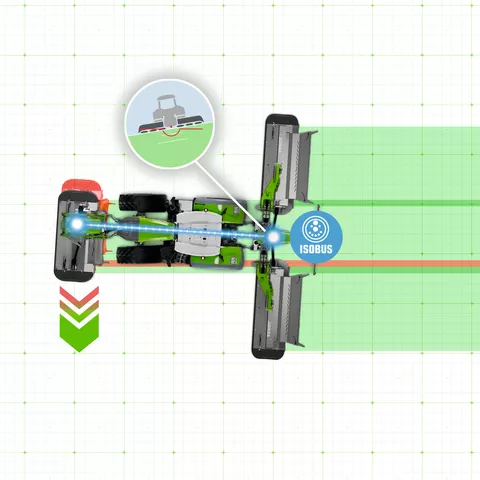

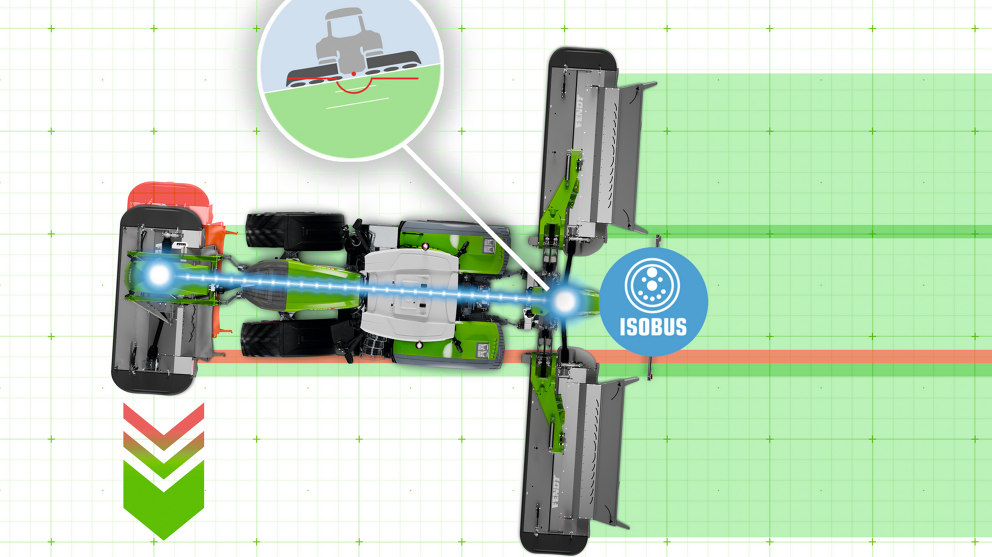

The completely newly developed series of Fendt Former two-rotor central delivery rakes offers six models with a working width of 6.90 to 10 metres and, for the first time in this rake segment, numerous optional ISOBUS functions. In addition to the proven features such as the patented SteerGuard or the double swing arm with cardanic rotor suspension, ISOBUS functions such as the unique Fendt proConnect ISOBUS system and Section Control are available for the first time. This means that Fendt covers the needs of every customer, from those looking for an entry-level models to those requiering smart machines with ISOBUS functions.

More information on the Fendt Former C two-rotor central delivery rake can be found IN THIS PRESS RELEASE.

Fendt integrates forage solutions

For the first time, Fendt presented implements from the Feucht factory at Agritechnica 2015 as part of its own product range. At that time, the machines were mainly green-painted products from the existing range.

Over the past nine years, both the Fendt product range and the production and development location for green forage solutions have been continuously expanded and improved. This means that the requirements of Fendt customers can be better met. The rising demand reflects the positive effects of investments in the development of an extensive product range and the expansion of production. Today, Fendt offers mowers, tedders and rakes for the global grassland market – from Europe to Australia and New Zealand.

Technical innovations in forage solutions

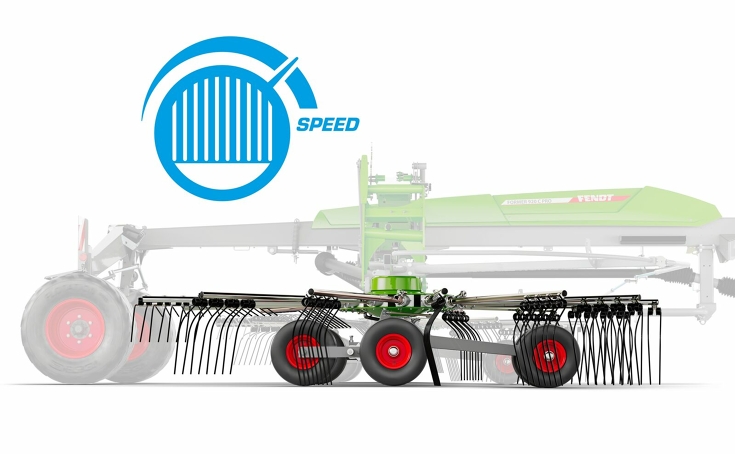

Developments such as the Streamline cutterbar, the automatic lateral displacement of the Fendt Slicer FQ front mower – controlled by data from the rear mower – the speed-dependent control of the contact pressure with the Fendt TurboLift cutterbar relief or the automated conditioner setting for the Fendt Slicer 960 KCB mower combination, which was honoured with the Silver DLG Innovation Award, demonstrate the further development of products for professional users.

Fendt FlexHigh

The latest development of the Fendt Former C two-rotor central delivery rake completes the range of smart Fendt Former rakes from two-rotor to four-rotor rakes with ISOBUS functions, such as the in-house development of the flexHigh rake height adjustment included in the Fendt proConnect ISOBUS package.

Compact and lightweight: The Fendt Twister 601 DN in alpine use

With its wide variety of machines, Fendt covers the needs of different customer groups. Specially developed compact and lightweight solutions for the Alpine region is part of the product range, as are machines for in-house mechanisation. With its range of ISOBUS-compatible grassland solutions, Fendt fulfils the requirements of professional farms and contractors. These include, for example, the Fendt Former 14055 PRO four-rotor rake or the Fendt Slicer 960 KCB rear mower.

Fendt Lotus 1250

The new developments of the green forage machines were preceded by numerous conversion and modernisation measures. Investments totalling EUR 21.6 million from 2018 onwards are evidence of the location's significant further development. The ground-breaking ceremony for the new assembly hall for mowers took place in 2018. SAP was implemented in the same year. This allows information from production to be managed more efficiently and orders to be processed more effectively. The Fendt Lotus tedder series was successfully integrated into production at the Feucht location in 2019. Further investments in 2020 and 2021 improved paint quality, assembly and logistics processes as well as quality control. These were rewarded with ISO certification, among other things.

In the years that followed, the logistics at the factory and delivery to dealers were comprehensively reorganised. Today, a new storage concept and the new logistics centre ensure high delivery quality of the machines.

The most recent remodelling at the Feucht location included the creation of a new dispatch area with several covered loading ramps, which now ensures that all machines can be dispatched nationally and internationally regardless of production times. This new division was also created under the leadership of Dr Ute David, who has been in charge of the production factory in Feucht since 01 May 2024. She was previously responsible for Sales & Operations Planning at the location.

Fendt factory in Feucht opens its doors to farmers

A new visitor concept for the factory was also developed this year. From October 2024, customer groups will be able to visit the Fendt factory in Feucht. As usual with Fendt, registration and appointment coordination are handled by the customer's Fendt dealer.