-

Products & Solutions

-

Agricultural Machinery

back to Overview

-

Tractors

-

Fendt 1100 Vario MT

from 376 kW / 511 hp to 495 kW / 673 hp

from 376 kW / 511 hp to 495 kW / 673 hp -

Fendt 1000 Vario

Fendt 1000 Variofrom 291 kW / 396 hp to 380 kW / 517 hp

Fendt 1000 Variofrom 291 kW / 396 hp to 380 kW / 517 hp -

Fendt 900 Vario MT

Fendt 900 Vario MTfrom 279 kW / 380 hp to 317 kW / 431 hp

Fendt 900 Vario MTfrom 279 kW / 380 hp to 317 kW / 431 hp -

Fendt 900 Vario

Fendt 900 Variofrom 217 kW / 296 hp to 305 kW / 415 hp

Fendt 900 Variofrom 217 kW / 296 hp to 305 kW / 415 hp -

Fendt 700 Vario Gen7

Fendt 700 Vario Gen7from 149 KW / 203 hp to 223 kW / 303 hp

Fendt 700 Vario Gen7from 149 KW / 203 hp to 223 kW / 303 hp -

Fendt 700 Vario Gen6

Fendt 700 Vario Gen6from 106 kW / 144 hp to 174 kW / 237 hp

Fendt 700 Vario Gen6from 106 kW / 144 hp to 174 kW / 237 hp -

Fendt 600 Vario

Fendt 600 Variofrom 110 kW / 149 hp to 154 kW / 224 hp

Fendt 600 Variofrom 110 kW / 149 hp to 154 kW / 224 hp -

Fendt 500 Vario

Fendt 500 Variofrom 91 kW / 124 hp to 120 kW / 163 hp

Fendt 500 Variofrom 91 kW / 124 hp to 120 kW / 163 hp -

Fendt 300 Vario

Fendt 300 Variofrom 83 kW / 113 hp to 104 kW / 142 hp

Fendt 300 Variofrom 83 kW / 113 hp to 104 kW / 142 hp -

Fendt 200 Vario

Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hp

Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hp -

Fendt 200 VFP Vario

Fendt 200 V/F/P Variofrom 58 kW / 79 hp to 91 kW / 124 hp

Fendt 200 V/F/P Variofrom 58 kW / 79 hp to 91 kW / 124 hp

e-tractors-

Fendt e100 Vario

Fendt e100 Variofrom 50 kW / 68 hp to 66 kW / 90 hp

Fendt e100 Variofrom 50 kW / 68 hp to 66 kW / 90 hp -

Fendt e100 V Vario

Fendt e100 V Vario55 kW / 75 hp

Fendt e100 V Vario55 kW / 75 hp

-

Fendt 1100 Vario MT

-

Telehandler

-

Fendt Cargo T955

Fendt Cargo T955123 kW / 171 hp

Fendt Cargo T955123 kW / 171 hp -

Fendt Cargo T740

Fendt Cargo T740100 kW / 136 hp

Fendt Cargo T740100 kW / 136 hp

Combines-

Fendt IDEAL

Fendt IDEALfrom 336 kW / 451 hp to 581 kW / 790 hp

Fendt IDEALfrom 336 kW / 451 hp to 581 kW / 790 hp -

Fendt C-Series

Fendt C-Seriefrom 225 kW / 306 hp to 265 kW / 360 hp

Fendt C-Seriefrom 225 kW / 306 hp to 265 kW / 360 hp -

Fendt C-Series SL

Fendt C-Serie SL225 kW / 306 hp

Fendt C-Serie SL225 kW / 306 hp -

Fendt L-Series

Fendt L-Seriefrom 192 kW / 260 hp to 225 kW / 306 hp

Fendt L-Seriefrom 192 kW / 260 hp to 225 kW / 306 hp -

Fendt CORUS 500

Fendt CORUS 500from 136 kW / 185 hp to 192 kW / 260 hp

Fendt CORUS 500from 136 kW / 185 hp to 192 kW / 260 hp

-

Fendt Cargo T955

-

Mowers

-

Fendt Slicer disc mowers

Fendt Slicer disc mowers

Fendt Slicer disc mowers -

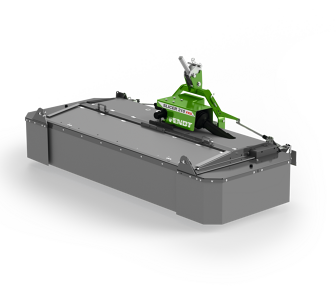

Fendt Slicer front mounted mower

Fendt Slicer front mounted mower

Fendt Slicer front mounted mower -

Rear mounted Fendt Slicer

Rear mounted Fendt Slicer

Rear mounted Fendt Slicer -

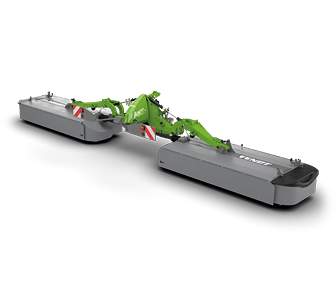

Fendt Slicer mower combinations

Fendt Slicer mower combiations

Fendt Slicer mower combiations -

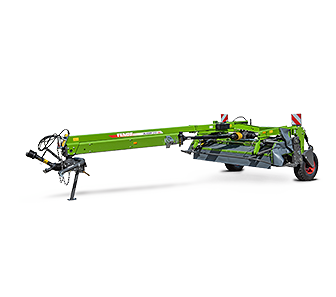

Fendt Slicer mowers towed

Fendt Slicer mowers towed

Fendt Slicer mowers towed -

Fendt Cutter

Fendt Cutter

Fendt Cutter

Forage wagons-

Fendt Tigo XR/VR/PR

Fendt Tigo

Fendt Tigo

XR/VR/PR -

Fendt Tigo ST/S/MS/MR/MR Profi

Fendt Tigo

Fendt Tigo

ST/S/MS/MR/MR Profi

-

Fendt Slicer disc mowers

-

Balers

-

Fendt Square Balers

Fendt Square balers

Fendt Square balers -

Fendt Rotana F

Fendt Rotana F

Fendt Rotana F -

Fendt Rotana V

Fendt Rotana V

Fendt Rotana V -

Fendt Rollector

Fendt Rollector

Fendt Rollector

-

Fendt Square Balers

-

-

Areas of Application

back to Overview

-

Fendt Alpine programme

-

Fendt Slicer Alpine

Fendt Slicer Alpine

Fendt Slicer Alpine -

Fendt Twister Alpine

Fendt Twister Alpine

Fendt Twister Alpine -

Fendt Former Alpine

Fendt Former Alpine

Fendt Former Alpine -

Fendt Tigo Alpine

Fendt Tigo Alpine

Fendt Tigo Alpine -

Fendt 200 Vario Alpine

Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hp

Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hp

-

Fendt Slicer Alpine

-

- Smart Farming

- Original accessories & technologies

-

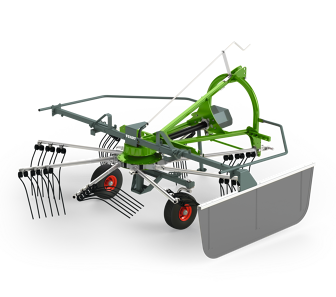

Agricultural Machinery

The Fendt Former C series of two-rotor central delivery rakes offers six models with a working width of 6.90 to 10 metres. High working speed with clean forage quality, a wide range of equipment options and a large number of optional ISOBUS functions characterise these Fendt Former models. The range includes standard models for those not needing ISOBUS functionality through to smart models for customers with high ISOBUS performance requirements.

The designation of the Fendt Former 920 C PRO model is made up of 920 for a maximum working width of 9.20 metres, C for "central delivery" or middle rake and PRO for the models with ISOBUS.

Model overview Fendt Former central delivery rake

Arbeitsbreite | Ohne ISOBUS | Mit ISOBUS |

6,90 – 7,60 m | Fendt Former 760 C | |

7,60 – 8,60 m | Fendt Former 860 C | Fendt Former 860 C PRO |

8,00 - 9,20 m | Fendt Former 920 C | Fendt Former 920 C PRO |

8,80 – 10,00 m | Fendt Former 1000 C PRO |

The ISOBUS control for the Fendt Former central delivery is fully integrated into the tractor terminal. This means that the functions can also be conveniently assigned directly to the tractor joystick. With the help of ISOBUS, drivers can set the working and swath width, the intensity of Fendt flexHigh or the raking height directly from the tractor cab. The ISOBUS control of the PRO models enables individual lifting of the rotors as standard configuration. An electro-hydraulic individual lifting can be ordered an optional for the standard models. The advantages of individual lifting: Particularly precise work, even with wedges or angled surfaces as well as on headlands, and double processing is prevented. This is complemented by the adjustable headland lift. The lift height of the rotors at the headland can be adjusted in five stages and is adjusted via the terminal.

Section Control for two-rotor central delivery rakes

For the first time in this rake segment, the ISOBUS Section Control function is available as optional for the Fendt Former PRO models. Section Control detects the areas being worked and automatically raises the rotor as soon as areas that have already been worked, such as the headland, are passed over. This reduces dirt ingress and wear, relieves the driver and increases the overall efficiency of the trailer.

ISOBUS for the Fendt Former with Fendt proConnect

The unique Fendt proConnect ISOBUS system is familiar from the Fendt Former four-rotor rake series and is available for the first time for two-rotor central delivery rakes. Fendt proConnect consists of the Fendt flexHigh and myMemory functions specially developed for rakes.

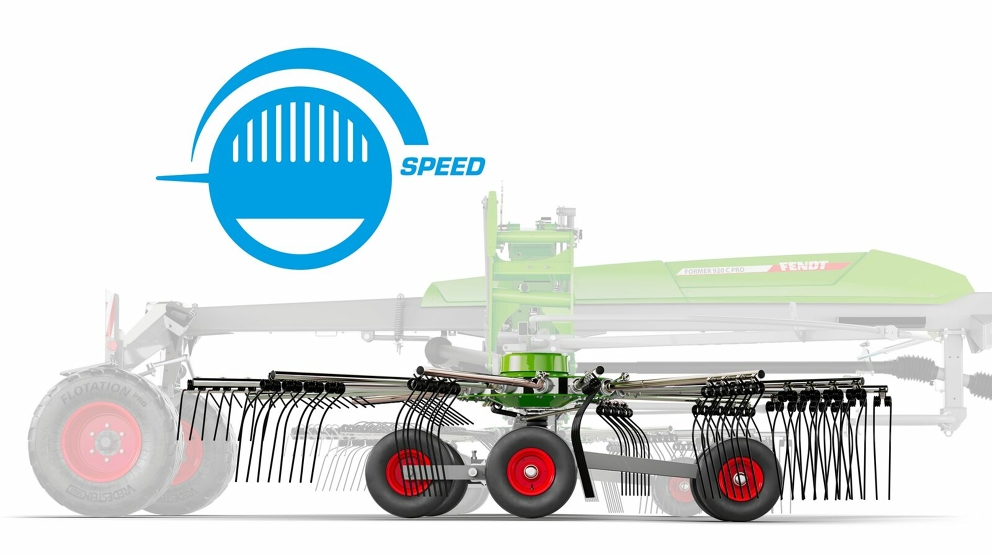

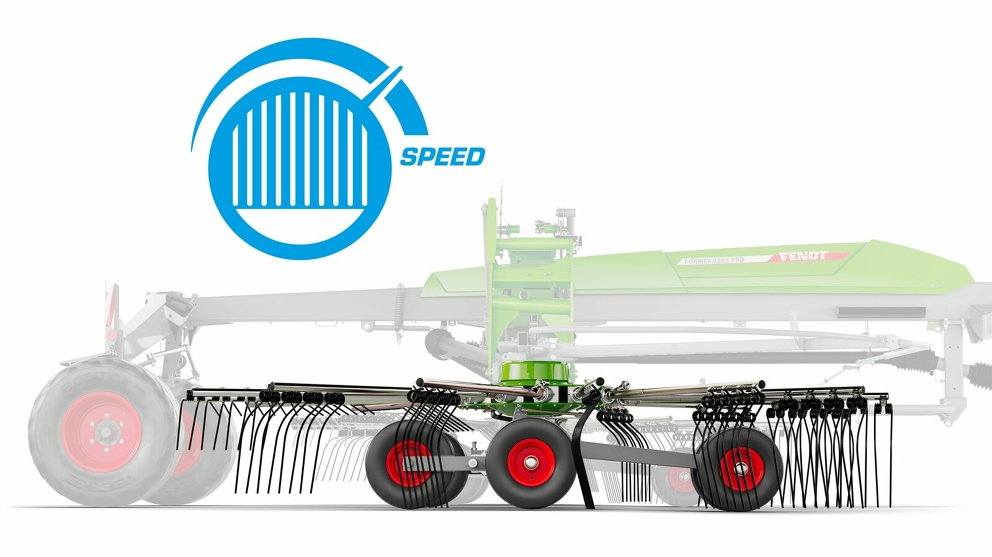

Optimum raking height at high speed

For optimum raking results, the Fendt Former adjusts the working height of the tines to the forward speed via the flexHigh automated raking height adjustment. If the tractor's forward speed increases, the speed-dependent system lowers the rotors and regulates the distance between the tines and the ground. In this way, raking losses are prevented. If the forward speed drops, the system raises the rotors to prevent dirt from entering. This significantly increases the area output even with high forage quantities. The speed-dependent control system reduces feed losses and feed contamination at the same time.

Fendt FlexHigh rake height adjustment

When stationary, the tines are completely raised. This intelligent control protects the turf, reduces dirt ingress and increases forage quality. If the raking height is optimised in every situation, this also reduces wear on the tines.

Setting memory shortens set-up times

The integrated myMemory rake management system stores settings such as the working width, swath width and raking height. At the push of a button, the machine moves into its most compact transport position when the work is done. At the next field, the previously saved settings are recalled at the touch of a button and the machine moves to the last settings fully automatically. This reduces operating errors and considerably reduces set-up times.

Easy to Use

In combination with an ISOBUS-capable tractor, all functions can be operated via the joystick and the tractor terminal. In addition, the user interface has been completely optimised for FendtONE. The simple and clear display makes it easy to operate the machine functions. If required, a joystick is also available to be retrofitted. The maintenance-free, bolted rotor head and long maintenance intervals of the PTO shafts reduce the maintenance costs. A hectare and hour counter makes it easier to calculate the work performed and qualifies the machine for an extension of the warranty.

Protected components

Forage solutions is mostly used in tight harvesting windows, which is why farmers rely on machines with a high level of operational reliability. The protected components of the Fendt Former two-rotor central delivery rake make a decisive contribution to its operational reliability. The patented rotary shaft steering system with Fendt SteerGuard is only available for Fendt rakes and is unique on the market. The straight course of the steering axle within the main frame protects the pivot shaft and still enables precise steering even after many years of use.

To protect the machine from possible damage, each rotor is equipped with its own independent overload protection. Features for working comfort such as the new hose cabinet with the weather-protected electronic plug, an indicator for the working width and the transport lock – both visible directly from the tractor cab – complete the superstructure.

Combines soil protection and manoeuvrability

Precise adjustment and control of the various components for ground tracking protects the sward and prevents dirt ingress. The Fendt Former has several functions that improve ground tracking. Well-known functions such as the jet effect and the double swing arm for the cardanic rotor suspension help to produce high-quality forage. The longitudinal and transverse tilt of the rotor fame can also be steplessly adjusted. The parallel lifting of the rotors was newly developed. Thanks to sophisticated kinematics, both rotors are raised parallel to the ground and only fold upwards once a certain ground clearance has been reached. When the rotors are set down, the control is reversed so that the control prevents the tines from piercing the ground and prevents forage contamination. The combination of large-dimensioned tyres and spring relief for the lift arms protects the ground. The standard spring relief on the lift arms shifts some of the weight of the rotors onto the main frame, making it easier for the rotors to travel over uneven ground. Tyres with a special tread pattern are also available as optional. These tyres combine high operational safety with a long service life.

The cam track can be adjusted quickly and easily without additional tools to adapt the swath shape to different harvesting conditions. This increases the throughput rate and, at the same time, the cutting quality of downstream collection machines. An automatically folding swath cloth is available as optional.

Axle options for the Fendt Former C

The steerable tandem axles of the rotors increase the manoeuvrability of the combination and are optionally available ex works. The weight of the rotor is distributed over the double contact area, the individual tyres are relieved and the turf is protected when cornering. The rigid tandem axles are fitted as standard on all Fendt Former PRO models. They enable a more even weight distribution and achieve optimum ground adaptation even in difficult terrain. Both tandem axles, rigid and steerable, are also available as optional for the models without ISOBUS functions.

Fast and convenient transport

The Fendt Former now has numerous functions that simplify transport and reduce the necessary set-up times to a minimum. These offer particular advantages in tight harvesting windows. The transport height of the Fendt Former 760 C, 860 C and 920 C models, including attached tine arms, is less than 4 metres. Three or four tine arms are also removable. This means that the transport height can be reduced even further and the rake can be stowed in a barn with a low clearance height if required. All other tine arms are firmly bolted, which reduces play and noise.

A new feature is the patented system for lowering the drive train in the transport position. It combines the advantages of a lower transport height and at the same time guarantees the benefits of a low centre of gravity thanks to the straight main frame with low maintenance requirements. In addition, the rake is now secured hydraulically during transport and requires no further work steps.

A new package with three high-performance LED work lights is optionally available for the Fendt Former PRO models. They optimally illuminate the rotors and the working area during long harvesting days, thus increasing work safety.