-

Products & Solutions

-

Agricultural Machinery

back to Overview

-

Tractors

-

Fendt 1100 Vario MT

from 376 kW / 511 hp to 495 kW / 673 hp

from 376 kW / 511 hp to 495 kW / 673 hp -

Fendt 1000 Vario

Fendt 1000 Variofrom 291 kW / 396 hp to 380 kW / 517 hp

Fendt 1000 Variofrom 291 kW / 396 hp to 380 kW / 517 hp -

Fendt 900 Vario MT

Fendt 900 Vario MTfrom 279 kW / 380 hp to 317 kW / 431 hp

Fendt 900 Vario MTfrom 279 kW / 380 hp to 317 kW / 431 hp -

Fendt 900 Vario

Fendt 900 Variofrom 217 kW / 296 hp to 305 kW / 415 hp

Fendt 900 Variofrom 217 kW / 296 hp to 305 kW / 415 hp -

Fendt 700 Vario Gen7

Fendt 700 Vario Gen7from 149 KW / 203 hp to 223 kW / 303 hp

Fendt 700 Vario Gen7from 149 KW / 203 hp to 223 kW / 303 hp -

Fendt 700 Vario Gen6

Fendt 700 Vario Gen6from 106 kW / 144 hp to 174 kW / 237 hp

Fendt 700 Vario Gen6from 106 kW / 144 hp to 174 kW / 237 hp -

Fendt 600 Vario

Fendt 600 Variofrom 110 kW / 149 hp to 154 kW / 224 hp

Fendt 600 Variofrom 110 kW / 149 hp to 154 kW / 224 hp -

Fendt 500 Vario

Fendt 500 Variofrom 91 kW / 124 hp to 120 kW / 163 hp

Fendt 500 Variofrom 91 kW / 124 hp to 120 kW / 163 hp -

Fendt 300 Vario

Fendt 300 Variofrom 83 kW / 113 hp to 104 kW / 142 hp

Fendt 300 Variofrom 83 kW / 113 hp to 104 kW / 142 hp -

Fendt 200 Vario

Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hp

Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hp -

Fendt 200 VFP Vario

Fendt 200 V/F/P Variofrom 58 kW / 79 hp to 91 kW / 124 hp

Fendt 200 V/F/P Variofrom 58 kW / 79 hp to 91 kW / 124 hp

e-tractors-

Fendt e100 Vario

Fendt e100 Variofrom 50 kW / 68 hp to 66 kW / 90 hp

Fendt e100 Variofrom 50 kW / 68 hp to 66 kW / 90 hp -

Fendt e100 V Vario

Fendt e100 V Vario55 kW / 75 hp

Fendt e100 V Vario55 kW / 75 hp

-

Fendt 1100 Vario MT

-

Telehandler

-

Fendt Cargo T955

Fendt Cargo T955123 kW / 171 hp

Fendt Cargo T955123 kW / 171 hp -

Fendt Cargo T740

Fendt Cargo T740100 kW / 136 hp

Fendt Cargo T740100 kW / 136 hp

Combines-

Fendt IDEAL

Fendt IDEALfrom 336 kW / 451 hp to 581 kW / 790 hp

Fendt IDEALfrom 336 kW / 451 hp to 581 kW / 790 hp -

Fendt C-Series

Fendt C-Seriefrom 225 kW / 306 hp to 265 kW / 360 hp

Fendt C-Seriefrom 225 kW / 306 hp to 265 kW / 360 hp -

Fendt C-Series SL

Fendt C-Serie SL225 kW / 306 hp

Fendt C-Serie SL225 kW / 306 hp -

Fendt L-Series

Fendt L-Seriefrom 192 kW / 260 hp to 225 kW / 306 hp

Fendt L-Seriefrom 192 kW / 260 hp to 225 kW / 306 hp -

Fendt CORUS 500

Fendt CORUS 500from 136 kW / 185 hp to 192 kW / 260 hp

Fendt CORUS 500from 136 kW / 185 hp to 192 kW / 260 hp

-

Fendt Cargo T955

-

Mowers

-

Fendt Slicer disc mowers

Fendt Slicer disc mowers

Fendt Slicer disc mowers -

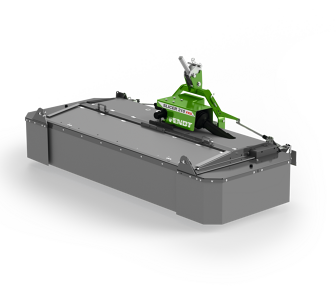

Fendt Slicer front mounted mower

Fendt Slicer front mounted mower

Fendt Slicer front mounted mower -

Rear mounted Fendt Slicer

Rear mounted Fendt Slicer

Rear mounted Fendt Slicer -

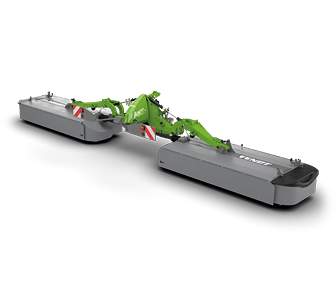

Fendt Slicer mower combinations

Fendt Slicer mower combiations

Fendt Slicer mower combiations -

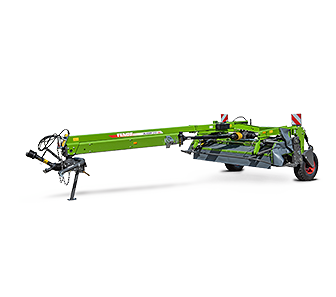

Fendt Slicer mowers towed

Fendt Slicer mowers towed

Fendt Slicer mowers towed -

Fendt Cutter

Fendt Cutter

Fendt Cutter

Forage wagons-

Fendt Tigo XR/VR/PR

Fendt Tigo

Fendt Tigo

XR/VR/PR -

Fendt Tigo ST/S/MS/MR/MR Profi

Fendt Tigo

Fendt Tigo

ST/S/MS/MR/MR Profi

-

Fendt Slicer disc mowers

-

Balers

-

Fendt Square Balers

Fendt Square balers

Fendt Square balers -

Fendt Rotana F

Fendt Rotana F

Fendt Rotana F -

Fendt Rotana V

Fendt Rotana V

Fendt Rotana V -

Fendt Rollector

Fendt Rollector

Fendt Rollector

-

Fendt Square Balers

-

-

Areas of Application

back to Overview

-

Fendt Alpine programme

-

Fendt Slicer Alpine

Fendt Slicer Alpine

Fendt Slicer Alpine -

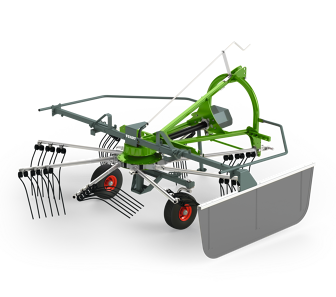

Fendt Twister Alpine

Fendt Twister Alpine

Fendt Twister Alpine -

Fendt Former Alpine

Fendt Former Alpine

Fendt Former Alpine -

Fendt Tigo Alpine

Fendt Tigo Alpine

Fendt Tigo Alpine -

Fendt 200 Vario Alpine

Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hp

Fendt 200 Variofrom 58 kW / 79 hp to 91 kW / 124 hp

-

Fendt Slicer Alpine

-

- Smart Farming

- Original accessories & technologies

-

Agricultural Machinery

Well tied – with net or film

Film binding is already available for the fixed-chamber baler-wrapper combinations. In order to offer customers of the variable chamber balers the same advantages, this technology has been transferred to variable chamber models of the Fendt Rotana.

With film binding, the bales are bound exclusively with film instead of net after the baling process by the Fendt Rotana 160 V Combi and then wrapped. The pure film binding reduces feed losses due to mould formation caused by air entrapment or freezing of the feed in the net at sub-zero temperatures.

Two gathering arms and the shaft binding system specially developed for the variable presses guide the binding material precisely and safely into the baler chamber. The shaft formation protects the sensitive film from damage. An electro-magnetic brake controls the pre-stretching of the net or film optimally according to the binder and its roll diameter. This optimises the stretch effect of the film and its adhesiveness, thus perfectly maintaining the density and quality of the bale. With film binding, the only waste material is film, which is much less contaminated and therefore easier to recycle.

The film binding system specially developed for variable chamber balers can save up to 3 metres of film per bale, as the shaft binding allows the film to be inserted wider and thus requires much less bundling.

The arrangement of the rolls on a magazine enables a quick change between film and net. This allows the user to quickly switch from silage to hay or straw bales as required.

Easy and fast refilling

A quick-change system for film and net rolls is available for the Fendt Rotana Combi balers. The roll magazine offers three storage spaces for rolls that are loaded ergonomically. With the help of the quick-change system, drivers can load the round balers directly in the morning for the entire working day. The system was specially developed to significantly reduce downtime whilst changing rolls.. Customers can choose between the Eco Load and Comfort Load options.

Machines with the Eco Load System have a simple loading chute that requires a little more muscle power. With Comfort Load, the driver places the roll in a padded carriage, lifts it and guides it up to the quick-change system. This requires little effort and the machine can be loaded directly from the ground, which significantly increases working comfort. An intelligent lever system makes it possible to switch between the three ready-to-tie rollers in a few simple steps. In addition, the easy operation and padded contact surfaces prevent damage to the net or film. This minimises downtime in the field and allows more bales to be baled per day.

Quickly closed – Speed tailgate

The faster the tailgate of the round baler opens and closes, the sooner the next bale can be made. The closing times of the Fendt Rotana tailgate have been optimised precisely for this purpose. Depending on the conditions, the Fendt Rotana 160 V Combi with the speed tailgate function bales up to thirty more bales per day than before. Farmers and contractors can thus use the working day even more efficiently and, if the weather threatens to change, can make more bales in the remaining time or go home earlier.

The option is available for all Fendt Rotana Xtra and Combi models.

Automated dry mass control

The bale size alone does not allow any conclusions to be drawn about the dry matter contained. Accordingly, the proportion of dry matter in the feed ration can vary from load to load . In future, with a variable chamber Rotana round balers, farms and contractors will be able to select how much dry matter a bale should contain before the baling process. Two synchronously operating sensors in the bale chamber record the moisture and mass of the bales. From this, the software calculates the dry matter content during the baling process. The round baler controls the bale diameter according to the entered target dry matter. This means that all subsequent bales have the same constant dry matter and can vary slightly in diameter. If, for example, the diameter of the first pressed bale is 1.25 metres, then the diameter of the following bales with a constantly equal dry matter ranges from 1.05 to a maximum of 1.35 metres.

The dry matter content enables transparent pricing in the bale trade. In addition, cattle farms can more easily align the mixing ratio of the components for the Total (Forage) Mixed Ration (TMR) in the cattle shed to the dry matter of the silage. This allows you to feed much more homogeneous rations and ensure a more constant energy & ingredient density. If livestock farms can calculate the composition of the feed more easily and reliably, this can increase milk yield or save concentrate feed and thus feed costs. Another advantage is the possibility to document the dry matter yield site-specifically and to derive recommendations for the following application.

Folds easily – Folding pick-up wheels

Until now, the pick-up wheels had to be detached from their working position and lifted into the transport device for road travel. Customers can now optionally order hydraulically or manually folding pick-up wheels for all Fendt Rotana Xtra and Combi. The hydraulically folding pick-up wheels are conveniently operated directly from the cab. This completely eliminates the need to lift and stow the pick-up wheels and the associated effort.

The pick-up wheels are self-steering and can be locked with a pin if required. This is particularly advantageous when driving backwards with the pick-up lowered and when working on steep slopes. In addition, this increases the service life of the pick-up wheels, as the wheel on the downhill side has a more stable track when driving on a steep slope.