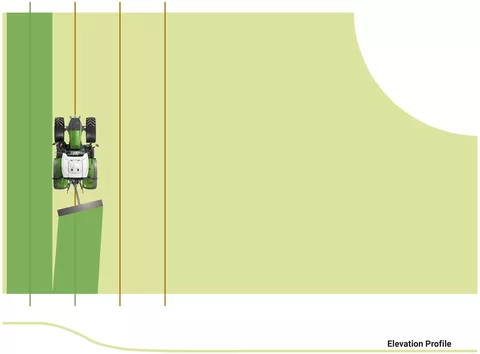

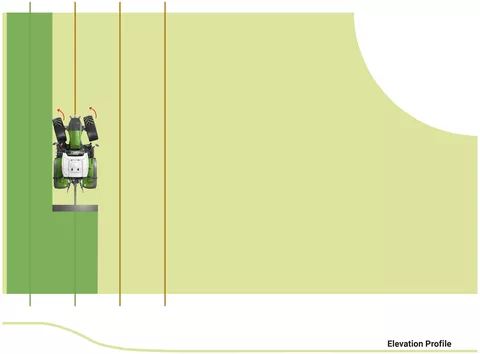

Guidance system for cropped terrain – Implement Slope Compensation

When working on slopes, trailed attachments can drift due to their own weight despite a guidance system, thus creating overlaps during the operation. Drivers must then manually intervene in the guidance system and correct the course. For example, you have to nudge waylines to keep the attachment following the along previous track correctly. With the new Fendt Implement Slope Compensation option, drivers can specify an override of the target slope. For this purpose, the driver sets a correction value per degree of slope. The tractor then automatically corrects its course depending on the current slope, so that the attachment optimally works its tracks. This increases the quality of work during tillage and seeding. Working comfort is increased as manual counter-steering is no longer required. A second receiver on the attachment is not necessary with this solution.

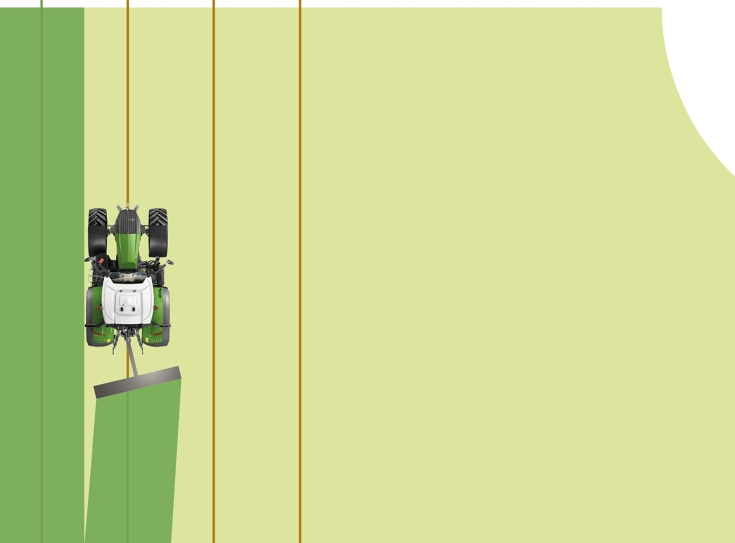

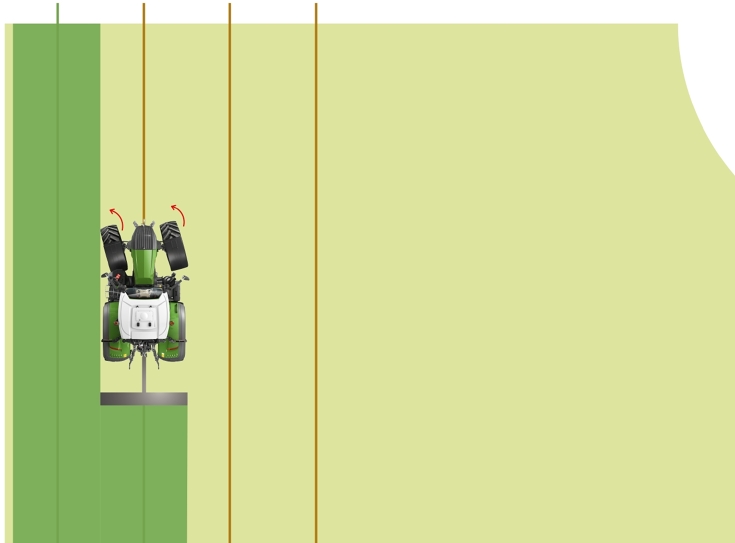

Machine control - Tramline Control (Level 1)

The Tramline Control (Level 1) update is now available for ISOBUS-capable machines in the Fendt Section Control function package. This function enables the exchange of certain information between the tractor and the seeder or planter. In order to optimally create tramlines, they are automatically calculated using the position data of the tractor. Based on the previously defined rhythm, the sowing or planting units are switched automatically and the tramlines are cut out. This makes work easier, as the driver or operator no longer has to pay attention to the tramline rhythm and can at the same time make the best possible use of functions such as Fendt TI Headland. The prerequisite is that the seeding or planting machines are equipped with Tramline Control. Tramline Control makes tramline planning much easier for farmers and contractors. In addition, matching the working widths of, for example, the seeder and field sprayer becomes obsolete.

Machine control – extension of TIM functionalities

The Fendt Tractor Implement Management (TIM) function is optionally available for all Profi+ machines with ISOBUS functionality. With TIM, appropriately equipped implements take over control of the tractor and the implement always works at its optimum. The TIM Hitch and TIM PTO function extensions now also enable the attachment to control the linkage, as well as the PTO shaft, for example, to automatically adjust the working depth using application maps. This means that deep tillage is only carried out where it is necessary. This protects the soil, saves fuel and is an active contribution to integrated agriculture.

Machine control – innovations for Variable Rate Control

With the new software update, the following innovation applies to the Fendt Variable Rate Control product: With large working widths, it was previously possible with Zone Control to apply different application rates per section width. The linking of Section Control and Variable Rate Control now makes it possible to reduce the application rate to zero on an ad hoc basis. Especially for spot spraying applications, this enables fast switching of the nozzle bodies. Drivers can use it to create zones in which no agents may be applied. This means that crop protection products are used even more precisely and efficiently. For exactly this purpose, the system can now also process spot spraying application maps. This makes it even easier to comply with legal requirements, especially in the vicinity of protected zones such as bodies of water or residential areas. This further reduces the use of crop protection products and is a way to achieve a more sustainable agriculture.

From November 2023, the new software update will be available for all tractors with FendtONE with the corresponding equipment.

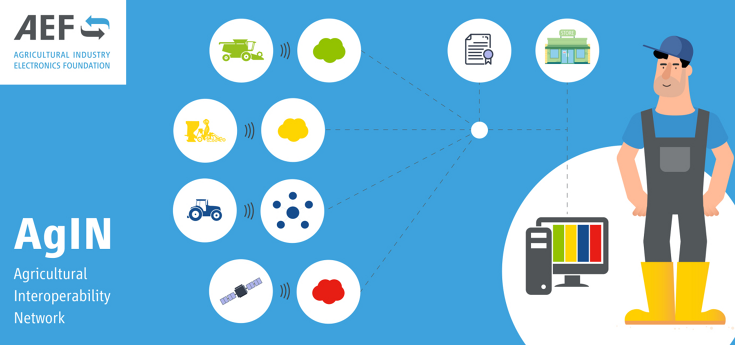

Fendt supports initiatives for simple data exchange

Fendt is heavily involved in the AgIN (Agriculture Interoperability Network) initiative of the AEF (Agricultural Industry Electronics Foundation e.V.) to develop a uniform environment for exchanging telemetry and task data. In the future, this will make it easier for farms to collect data from mixed fleets and transfer it to the farm management system of their choice. AGCO is one of the founding members of AEF and, as such, has been instrumental in the development of the ISOBUS standard. An AEF pilot project is planned for 2024.