High operating capacity and the resulting battery volume and weight make high demands when developing battery-electric driven agricultural machinery. To keep the pressure on the soil as low as possible, the weight of the e-vehicle cannot be significantly higher than that of a vehicle with a combustion engine. Consequently, this requirement limits the size of the battery and so also the operating duration of the tractor. For example, the newly developed Fendt e100 Vario achieves an operating time of about 4-6 hours with a single rotor rake working at half load. One starting point for optimising and promoting practicality is extending the vehicle’s working time with a range extender.

The Fendt e100 Vario has been developed for use with special crops, such as fruit and vegetable cultivation, on farms with livestock as well as on agricultural business that produce their own energy, or also use by local councils. The drive train of the Fendt e100 Vario consists of the battery with an electric motor and the Fendt Vario transmission. The machine has three different operating modes – Eco Mode with 50 kW, Dynamic Mode with 55 kW continuous output and Dynamic Mode + with short-term peak performance of up to 66 kW (90 hp). Innovations such as a Stop & Start function or a foot button for increased recuperation exploit the energy particularly efficiently.

Twice the operating time

A range extender with a capacity of about 100 kWh doubles the operating time. This means the tractor can run with an implement, such as an electrically-driven hoe under partial load, for one full working day without having to stop to charge up again. The range extender was developed together with BlueWorld and includes parts such as a fuel cell and methanol tank. Chemical reactions in the range extender generate electrical energy out of methanol. Combining a fuel cell and green methanol significantly cuts emissions.

The range extender is fully ISOBUS-capable and is controlled directly from the cab via the terminal in the tractor. It can be installed at the front or rear of the tractor and is supplied via the AEF interface with the DC voltage circuit of the vehicle with up to 15 KWh energy per operating hour. This means the tractor directly consumes the energy generated by the range extender. There are no losses caused by intermediate steps such as charging the battery and the energy is used optimally.

It also stands out thanks to more user-friendliness in comparison with a classic diesel emergency generator and it will also be possible to use it as a power-to-grid solution in the future. So the range extender can be used directly as a source of energy and in addition to the e-tractor can also safely operate another agricultural machine, such as a milking robot in the event of a power cut or air conditioning for livestock. This solution will reduce dependence on the electricity grid.

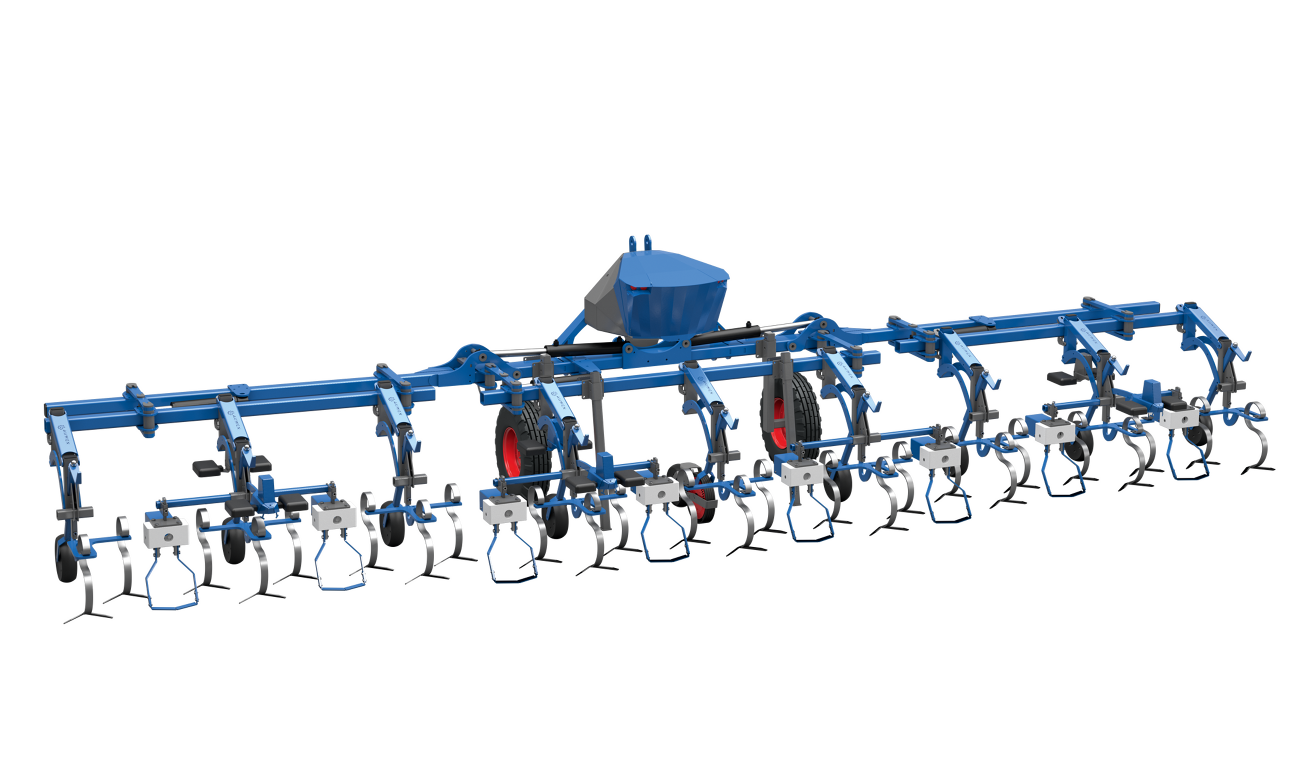

Fully electric driven hoe

What is decisive for mechanical weeding is the interplay between the use of specialised machines at the right point in time during a short time window. Added to the background of the Farm to Fork strategy is the requirement for Co2-neutral types of drive. The Fendt e100 Vario directly supplies the electrically operated and modular hoe via an AEF plug socket, converting the 700 volts provided by the vehicle into 24 volt DC voltage using a DC-DC converter. This avoids classic conversion steps, such as generating the necessary electrical output through a hydraulic motor with an alternator, and the associated much higher losses of energy.

With purely electric drive the tractor and implement use the energy available particularly effectively. The total efficiency of the combination rises to up to 92 per cent and losses are drastically reduced. This is particularly reflected in operating times. In this manner a combination with a battery-electric tractor and a hydraulically-driven intra-row hoe can achieve an operating time of up to eight hours. A combination of a battery-electric tractor and an electrically-driven intra-row hoe can achieve an operating duration of up to 10 hours in the lower partial load area. If the tractor also has a range extender with optimised efficiency in the partial load area of the fuel cell, the operating duration of the combination rises disproportionately to up to 25 hours. Breaks for charging are reduced to a minimum and short working windows are optimally used. This creates the necessary pre-conditions for future autonomous operation.

Autonomous control of the hoe

Mechanic weeding in particular demands specific specialist knowledge from the driver in terms of botany, machine operation and recognising anomalies in the crops. Agricultural businesses are finding fewer and fewer trained staff who can carry out time-consuming mechanical weeding properly. To help drivers, achieve good work results at the same time and use energy as efficiently as possible, the hoe is controlled autonomously and fully electrically. Two cameras control and monitor two hoe modules each. The front camera identifies the position and type of plants and differentiates between crops and weeds. The rear camera monitors the work result of the weeding. With dual camera control the hoe purposefully works only on those points where weeds have to be removed, both between and within rows. This control system with the aid of automatic image recognition helps the driver, increases the quality of the work and avoids the use of crop protection agents. The comprehensive sensors will form the basis for fully autonomous operations of the combination of tractor unit and hoe in the future, because the second camera takes on the driver’s control function.