The rotor of the Fendt Tigo impresses with its strength and huge output. The 25 mm wide rotor tines with Hardox contact surfaces, makes the Fendt Tigo stand out from the crowd with its quality of cut. The grass is fed exactly through the narrow cutting gap and has no alternative way out. It is actively conveyed through the table while the six spiral rows of tines of the rotor provide for an efficient, precise cut. The rotor tines pull gently at an angle of more than 90 degrees out of the forage, which guarantees gentle discharge of the feed. With a feed channel of more than 1 m², the feed is carefully carried to the loading space even under difficult operating conditions. You thus achieve a precise quality of cut without crushing and optimum quality pre-compacted feed.

Unique efficiency that'll make you smile.

Fendt Tigo MR and MR Profi.

Impressive performance

Hard at work the whole season through.

Fendt Tigo ST, S and MS.

Pure protection of the forage

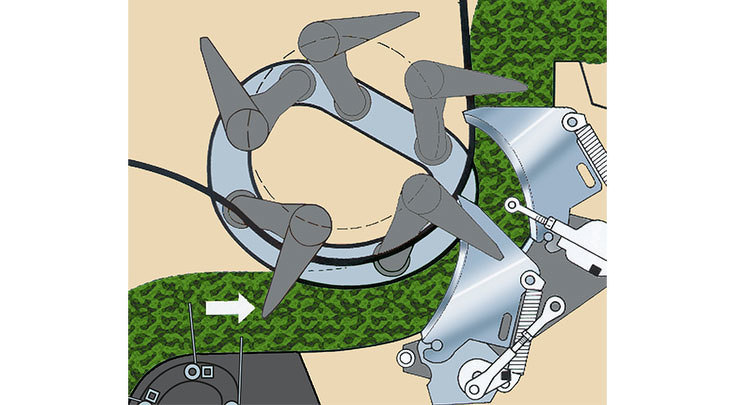

The heart of the Fendt Tigo ST, S and MS is the cam track-controlled loading unit. The kidney-shaped cam track guarantees optimum control of the individual conveyor rakes. The load peaks are optimally distributed, thanks to separate bearings on each individual rake. This makes them extremely precise. The double tines of the three conveying rakes pull straight back out of the forage hive and thus prevent the forage from being squashed. Thanks to this fork effect, the forage is transported loosely and in layers, gently and evenly, into the loading chamber. With the optional extension to four or five conveyor wings, the machine's conveying capacity can be increased.

Driving forward

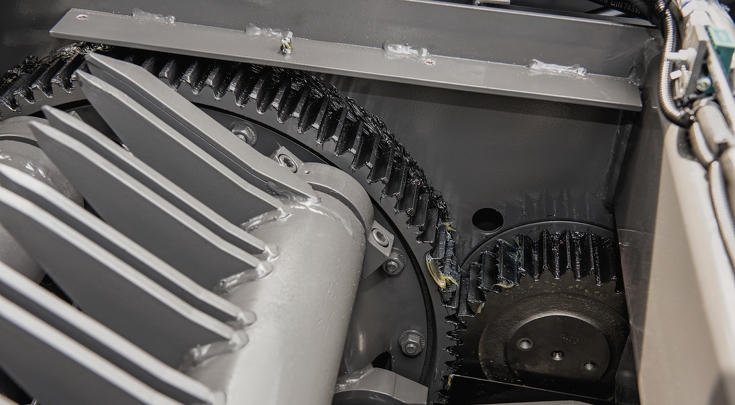

The Fendt Tigo ST, S and MS are truly special. It is the only wagon in its class to be driven directly via a robust gear drive. This makes this drive suitable for changing requirements and is extremely smooth running. Because they have no chain drives, the Fendt Tigo MS, S and ST run very smoothly for a pleasant working environment. There are no chain lubricants to drip onto the feed and contaminate it.

Maintenance instead of waiting

Each of the five conveyor swing arms are mounted separately on both sides in a closed roller bearing, and have a central lubrication system. The standard lubrication bars on the charging unit and the cam track prevent the lubricating film from breaking and make this model extremely low-wear and easy to maintain.

Undivided attention

To ensure an even and smooth forage flow, the Fendt Tigo ST, S and MS models have single-section conveyor swing arms. The central cutting process prevents tearing, as with a split or offset swing arm arrangement. The result is precisely cut, high-quality feed.