Redefine your harvest with our combine harvester.

The Fendt IDEAL was developed in the global AGCO Centres of Excellent in harvesting technology. Countless farmers and contractors from around the world were asked what combine requirements would make their IDEAL harvest. It's the culmination of this customer input, the combined experience of our developers and the chance to test the Fendt IDEAL all year round in different regions under the harshest operating conditions, that make the Fendt IDEAL the most modern and innovative combine on the market.

Model overview

| IDEAL 7 | 355 kW | 483 hp |

| IDEAL 8 | 404 kW | 549 hp |

| IDEAL 9 | 485 kW | 660 hp |

| IDEAL 10 | 581 kW | 790 hp |

Fendt Virtual Showroom

Discover the Fendt combine harvester in our virtual machine showroom.

The detailed 3D all-round view gives you insight into selected features such as the cab, cutterbar, grain tank and more.

Use the arrows to click your way through the Fendt Forum to the interior of the machine.

The detailed 3D all-round view gives you insight into selected features such as the cab, cutterbar, grain tank and more.

Use the arrows to click your way through the Fendt Forum to the interior of the machine.

Your IDEAL Story

Combine customers from around the world tell their IDEAL Story

Immerse yourself in moving stories from our project "Your IDEAL story". Customers from around the world are sharing their IDEAL experiences and how the IDEAL combine has revolutionised their harvest. Together with them and our experts, we exchanged ideas and collected valuable feedback to make the IDEAL combine even more powerful.

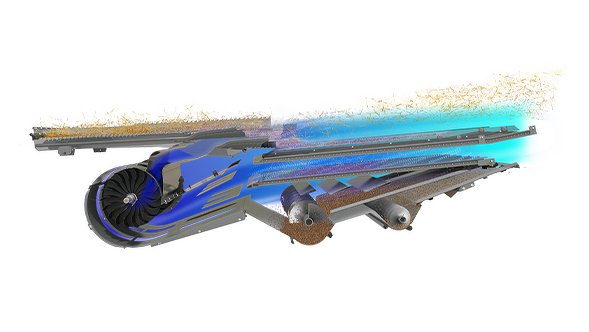

Fendt IDEAL combine harvester

More output.

More performance.

It's more user friendly.

It is time for new dimensions.

Exceptional conditions require exceptional performance – both from us and our machines. A clear view of the cutter unit and feeding with easy ergonomic steering. IDEALdrive brings ergonomics and efficiency to your working day.

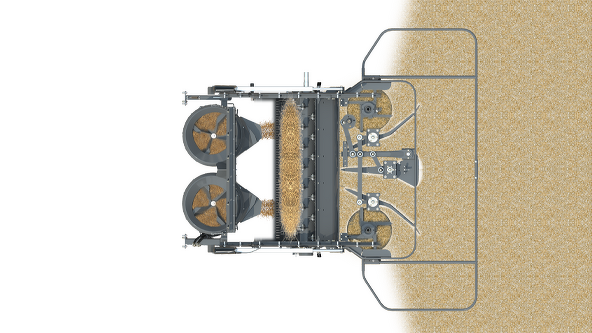

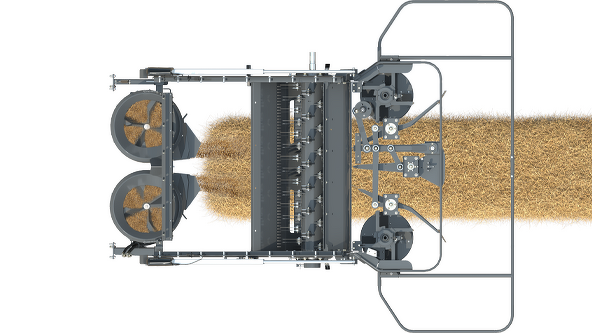

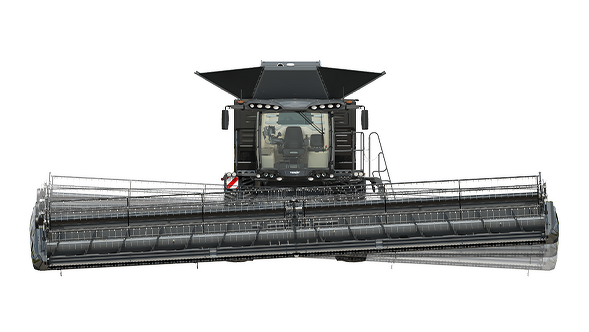

PowerFlow tables

Our PowerFlow cutter units stand out for their robust, solid and durable design. The PowerFlow belts actively drive the crop, including ears, into the machine. This means the material flows evenly, and the threshing system's potential is fully exploited and protected from stones. The large intake auger delivers impressive production capacities. The reel is hydraulically driven. You can have the system adjust the reel speed automatically, which means less effort for the driver. The PowerFlow cutting unit offers enormous flexibility, switching easily between rapeseed and grain. Bothsided vertical knives ensure clean crop edges. For quick and easy transport, the stalk dividers just fold away. There are various Fendt PowerFlow tables to choose from for the different IDEAL models, the widest version spanning 12.22 m or 40 ft.

12,22 m

maximum width

Always in the right position

With TerraControl™ table guidance you have perfect control over the widest attachments. TerraControl™ guides the attachment fully automatically at a perfect distance from and perfect inclination to the ground, working together with various functions you can use for the best results. This includes work height adjustment, resetting, ground pressure, various pre-selectable cutting heights, lifting when reversing, reel speed, positioning and headland management – everything fully automatically.

Powerful hydraulics

The lift cylinders on the Fendt IDEAL combine also provide easy clearance even with wide and heavy attachments. On the IDEAL 7 and 8 the cylinders measure 85 mm in diameter and can lift up to 5 tonnes. On the high-end models, IDEAL 9 and 10, the cylinders measure 92 mm in diameter and can lift up to 6.5 tonnes. The lifting design gives a maximum ground clearance of 1270 mm in the up position. Two cylinders on the crop elevator compensate for tilting. They respond quickly and precisely to changing surfaces and compensate up to +/-8°.

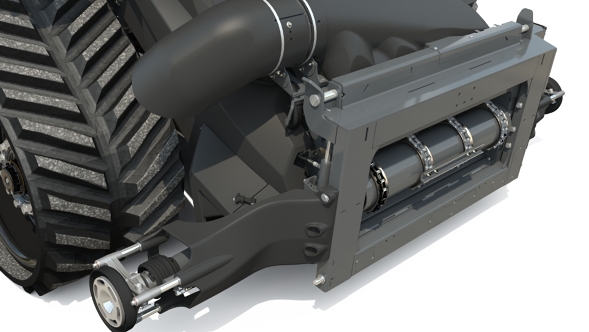

Fendt Autodock™ Crop elevator

Short setup times mean more time for harvesting. Fendt Autodock™ automatically couples the attachment within 5 seconds, setting standards in terms of ease of use. You don't even have to leave the driver's seat. Once the attachment is added, 4 hydraulic cylinders complete the connection. A hydraulic cylinder in the middle of the crop elevator frame mechanically locks the attachment. At the same time, two couplings push out to connect the PTO drives. Autodock™ connects the multi-coupler separately to the attachment and the machine. An RFID code, the 'Ag tag' detects the attachment and retrieves the last settings used for that unit.

Dust extraction on the crop elevator

The dust extraction system draws in the dust generated during threshing, it is vented to the side of the machine. The driver benefits from better visibility. The dust extraction system can be easily adjusted via the terminal in the cab.

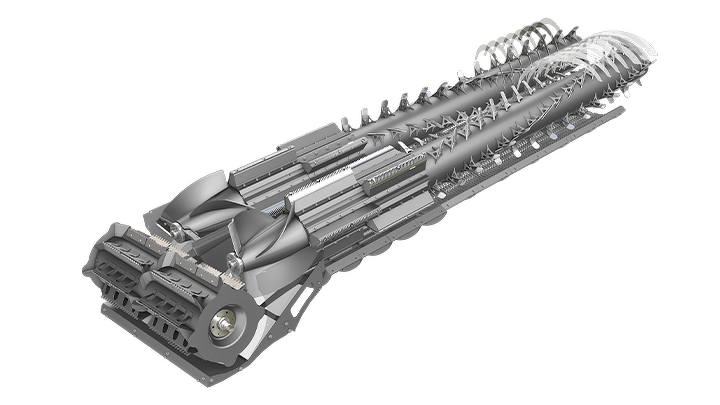

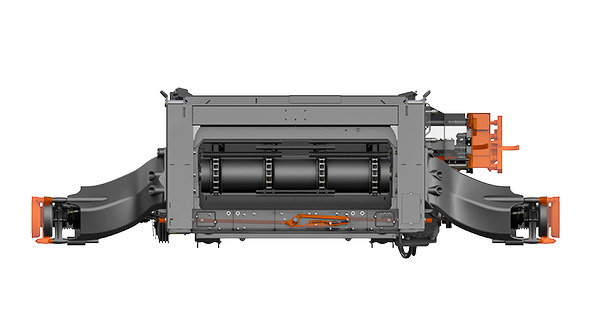

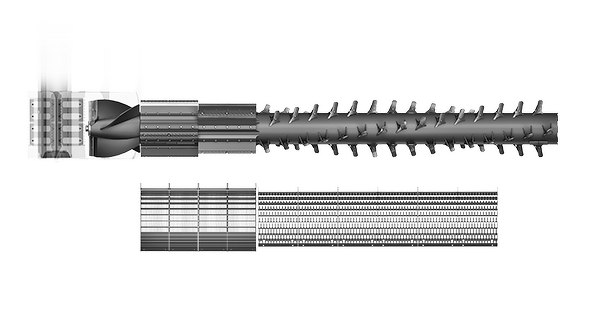

The Helix processor – simply unique

All components of the rotors such as the rasp bars and rotor tines are arranged in four rows like a helix. The front part of the rotors consists of four rasp bars installed lengthways which loosen the grains from the ears. The concaves below that are available in different designs for the best results in any application. They can be replaced quickly and easily from the side, depending on the application. The gaps between concaves are hydraulically adjusted up to a maximum of 35 mm. The rotor tines are tilted 20° to the rear, which divides the crop into the helix sections and reliably and gently runs it around the rotor. This prevents unexpected load peaks on the rotor and there are no edges for the product to stick to.

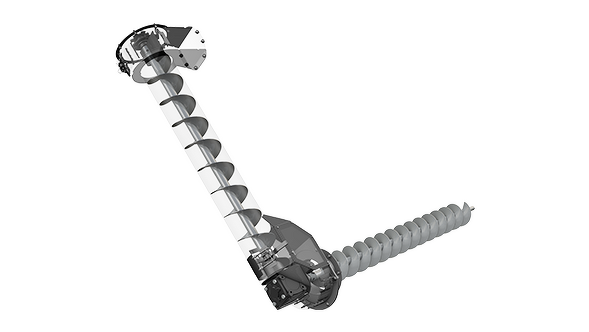

RotorFeeder feeding drum

The 600mm wide RotorFeeder feed drum feeds the

crop from below to the rotors, guaranteeing the best threshing results. The RotorFeeder speed is automatically controlled in proportion to the rotor speed – always at 70% of the rotor speed. Because the speed is adjusted to best match the rotor speed and the large transfer area, the straw is kept intact. The RotorFeeder also uses far less power during this process. A constant flow of crop is guaranteed by the optimal transfer.

crop from below to the rotors, guaranteeing the best threshing results. The RotorFeeder speed is automatically controlled in proportion to the rotor speed – always at 70% of the rotor speed. Because the speed is adjusted to best match the rotor speed and the large transfer area, the straw is kept intact. The RotorFeeder also uses far less power during this process. A constant flow of crop is guaranteed by the optimal transfer.

Gentle feed, low power requirement

The height of each rotor tine is 140 mm. Perfectly separated grain without damaging the product too much in too confined a space. In turn you get high straw quality and best threshing at low power. The threshing system is also distinguished by its simple configuration. The operator only needs to change the rotor speed range and the concave clearance.

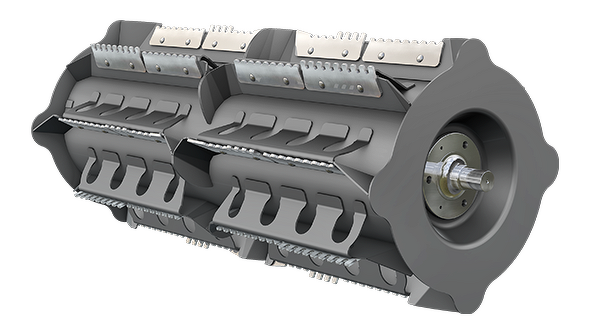

Triple fan

The powerful Cyclone cleaning fan consists of three fan units with open sides for maximum air output. The fan speed can be hydraulically adjusted between 250 and 1400 rpm, to give you different speeds quickly and efficiently. The powerful airflow is split from the first drop stage, with a constant air flow generated over the entire length of the shaker shoe, giving you the best cleaning results.

Separate post-threshing

Specially designed returns for maximum performance and the best threshing. The product is threshed out by the auger and passed on to the grain pan. This prevents any separating potential being lost at the processor. Threshing occurs between the auger and the interchangeable covers, which can be serrated or smooth depending on the intensity you want.

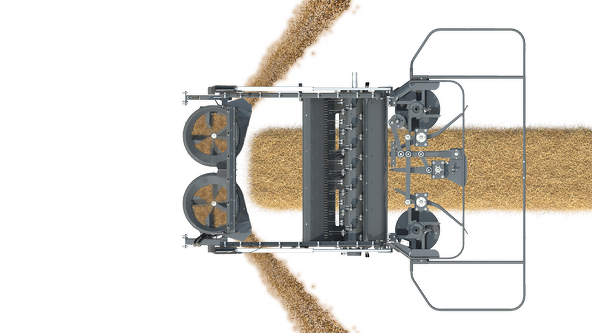

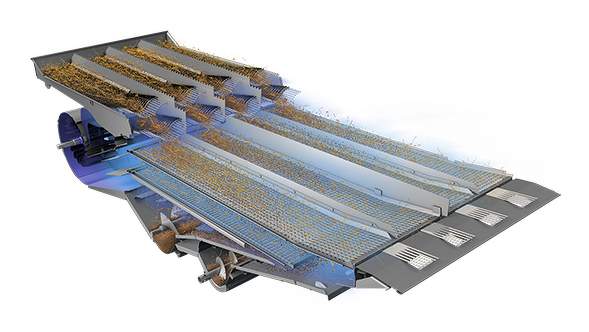

Superior cleaning

The long preparation floors, high partitions and the long shaker shoes provide for exceptional cleaning in the Fendt IDEAL. Most short straw and chaff is separated from the grain on the first drop between preparation floor and intermediate floor. The second drop to the top sieve then separates the impurities further. A strong air flow ensures perfect cleaning results. The longest sieves on the market with the fitted partitions mean optimal grain purity. In order to deliver the best results under all conditions, the opening range of the sieves can be conveniently and easily electrically adjusted from the cab. The IDEAL 10 features curved drop steps. Thanks to the curved shape, the heavy grains gather in the lower part of the step, while the laws of physics mean the lighter parts of the crop flow are in the top section. The curved steps allow for a wider air outlet, thus the air volume can be substantially increased.

Engines & reversible fan

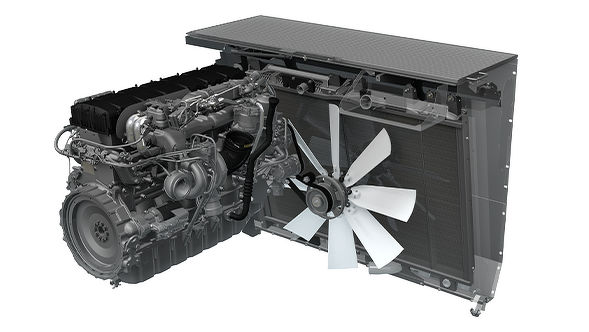

MAN and AGCO Power engine

To give you the best overall package, the 4 different Fendt IDEAL models also work with 4 different engines, which are perfectly adapted to the potential output of the IDEAL 7, 8, 9 and 10. Maximum fuel efficiency can only be achieved with an engine that is perfectly matched to the machine. The IDEAL 7 is powered by a 9.8-litre AGCOPower engine producing 476 hp and the IDEAL 8, 9 and 10 models use three different MAN engines. All engines comply with Emissions Stage V regulations, and are noted for their long service intervals.

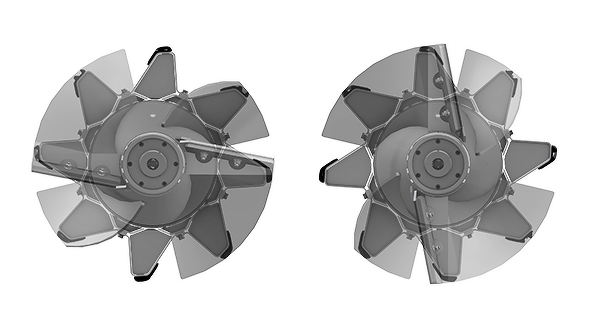

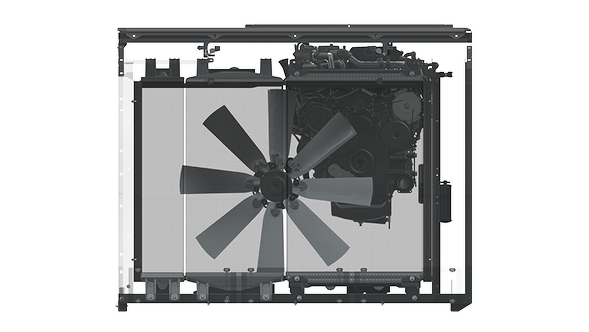

Revolutionary AirSense® Cooling

Cooling is a crucial part of ensuring the engines always run efficiently and reliably. AirSense® Cooling was developed for the Fendt IDEAL. The idea is to provide maximum cooling capacity with minimal cleaning effort. AirSense® Cooling consists of a 950 mm reversible fan and a

cooling area of 2.7 m². The air is extracted centrally through a radiator grille on the top side of the Fendt IDEAL. Depending on the temperature and time, the fan automatically changes its direction of rotation and reliably fans the cooler.

cooling area of 2.7 m². The air is extracted centrally through a radiator grille on the top side of the Fendt IDEAL. Depending on the temperature and time, the fan automatically changes its direction of rotation and reliably fans the cooler.

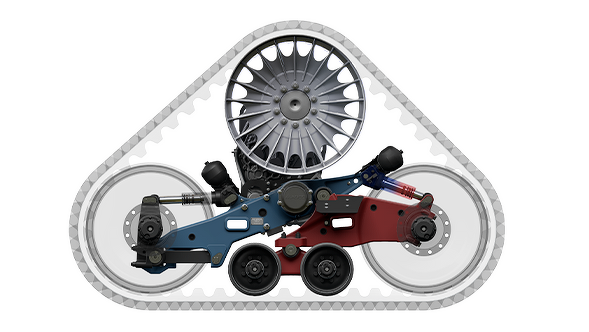

Fendt IDEAL Chassis

Slim mover

The slimline chassis of the Fendt IDEAL combine also allows for large surface areas in your tyre configuration, with an outside width measuring less than 3.3 m with 800/70R38 wheels. Even Fendt IDEAL combines with ParaLevel slope compensation, which makes adjustments for inclines of up to 14%, can have 800/70R38 wheels on the front axle. This will keep your transport width under 3.5 m.

Maximum propulsion

The IDEAL automatically switches to 4WD mode independently and intelligently only when the adjusted pressure of the front axle is reached. This means that the AllDrive axis supports the IDEAL only where necessary to deliver full traction. With the differential lock on, the AWD is permanently on. When you steer the differential lock turns off, and after the manoeuvre comes back on again. With this, the IDEAL saves on fuel and protects the axle.

The transmission on the Fendt IDEAL

Fendt MotionShift

The Fendt IDEAL gearbox offers two gears with a speed range of 0-15 km/h or 0-40 km/h. Fendt MotionShift allows you to shift both gears conveniently during the ride using a button on the armrest. The speed can be easily controlled via the multi-function joystick. In CVT mode, the speed starts at 0 km/h. The IDEAL's acceleration is linked to the joystick position. Enable the unique Hookup mode on the armrest and the Fendt IDEAL reacts proportionally to joystick movements. This makes light work of coupling headers.

Workplace with the best view

The Fendt VisionCab was designed to offer you the perfect workplace with the best view of the header. It does this with a window area of 5.75 m² and a 180° panoramic view. The low noise level of just 73 db creates a pleasant working atmosphere. The generous driver's cab means even long-legged drivers can enjoy a comfortable seat.

180°

All-round view

Everything under control

The simple and intuitive operation of the Fendt IDEAL is all down to the armrest. It features a handy joystick and the membrane/toggle button for machine functions. There is also a small digital display for the key machine settings. The Varioterminal 10.4" also allows you to easily adjust the machine by tapping or by pressing a button. For the advanced machine functions of the IDEALharvest™, click your iPad into the stable and practical holder and run the application.