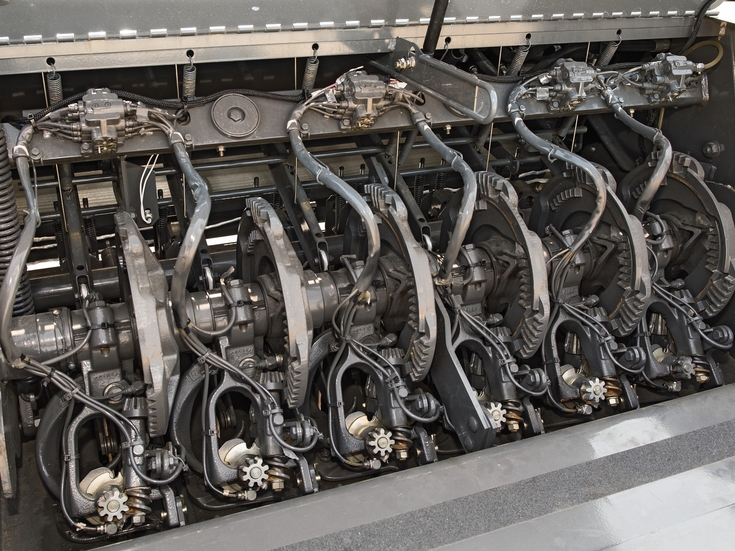

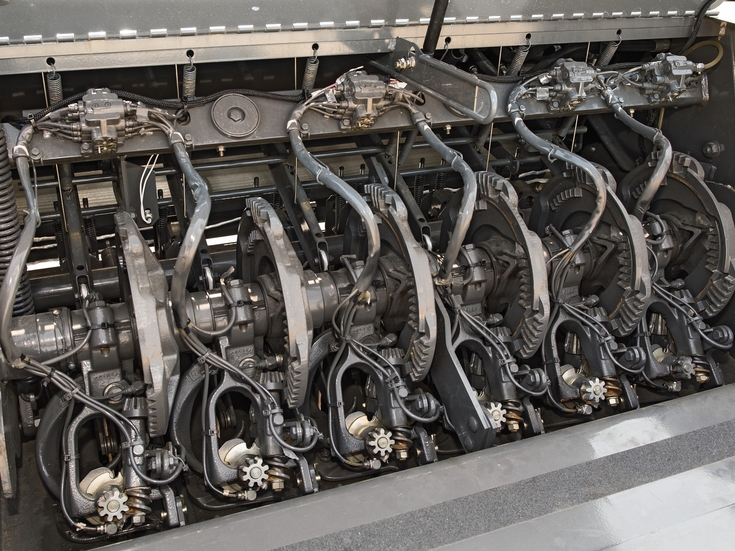

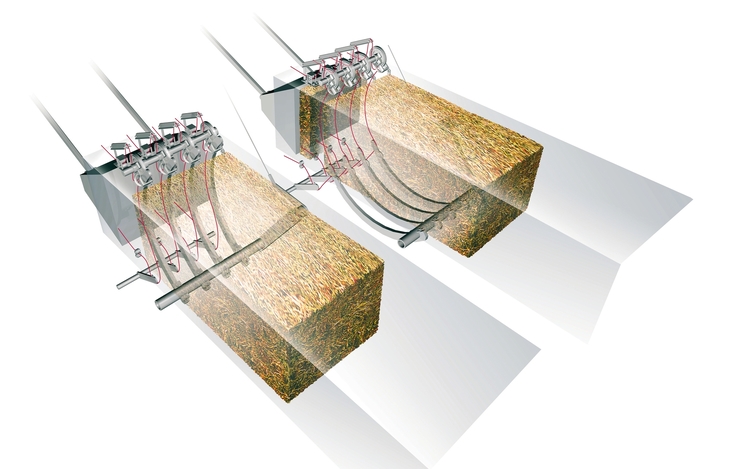

The tried-and-tested double knotter in the Fendt square balers guarantees reliable tying, even under high compression pressure.

Double knotted and securely packed.

Secure tying

The double knotter system in the Fendt square balers was developed in Hesston and has been optimised continually over 30 years and is one of the best knotter systems in the industry today. Each bale is tied securely with six knotters on a 120 cm wide channel and four knotters on a 80 cm wide channel. Two knots are produced during each tying procedure. Through the double knotter system, the twine holder and the needle are only subject to loads during the tying process. This guarantees less wear and higher operational security.

Secure tying

The double knotter system in the Fendt square balers was developed in Hesston and has been optimised continually over 30 years and is one of the best knotter systems in the industry today. Each bale is tied securely with six knotters on a 120 cm wide channel and four knotters on a 80 cm wide channel. Two knots are produced during each tying procedure. Through the double knotter system, the twine holder and the needle are only subject to loads during the tying process. This guarantees less wear and higher operational security.

Durable and protected

The bearings in the knotter area are sealed and protected. They have a long lifetime and low maintenance requirement. The knotter is lubricated through the centralised lubrication system. The duration and intervals for the lubrication can be adjusted to the prevailing conditions using the Varioterminal in the tractor.

Optimal access

The knotters that can be lifted up individually ensures optimum access for maintenance and servicing.

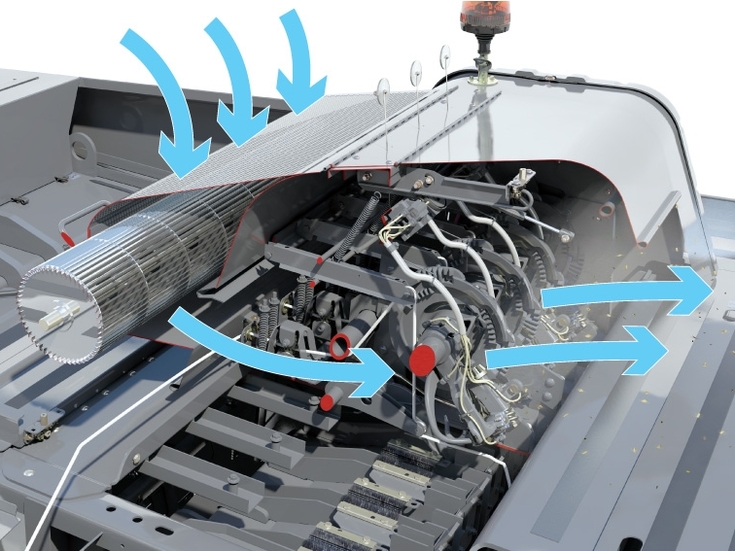

Cross-flow fan

The standard specification cross-flow fan maintains a constant flow of air over the entire knotter area, which thoroughly clears all debris from the knotter area.

Uniform twine feed

The twine is guided through the knotter brakes for uniform twine feed to the knotter.

Nothing is left to chance

A safety rod connected to the piston drive reliably protects the pins in the event of a broken shear pin.

Maximum twine supply

Smart and good-looking

The Fendt square baler is not only good-looking, it is also very functional. Large side panels that open provide an optimum overview of the fill level of the twine box. A twine storage capacity of 30 rolls ensures there is enough material for long work days. The balls of twine are stored at a 30° angle, which means the twine cannot slip or catch.

Smart and good-looking

The Fendt square baler is not only good-looking, it is also very functional. Large side panels that open provide an optimum overview of the fill level of the twine box. A twine storage capacity of 30 rolls ensures there is enough material for long work days. The balls of twine are stored at a 30° angle, which means the twine cannot slip or catch.

Optimal overview with maximum twine volume

With 30 balls of twine on board, it is possible to continue baling on long days without stops. If the twine runs out, it can be refilled and knotted without a problem, even in the dark, thanks to the sophisticated lighting concept.

"Easy-Fill" – guarantees easy filling

With the unique “Easy Fill” storage system, it is easy to fill the twine box. A V-shaped insert and a 30-degree tilt prevent the balls of twine from slipping when driving. The optimum position of the balls of twine means the knots are tied quickly. A mesh screen, fitted in advance, prevents the twine from unravelling by itself.

Twine box with maximum capacity

During the season, one should only have to deal with as little maintenance work as possible. With 30 balls of twine on board, it is possible to continue baling on long days without stops. When the twine runs out, suitable twine can be delivered through AGCOParts at short notice.