Bundled power – hour after hour

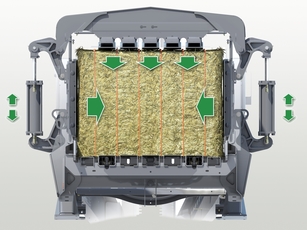

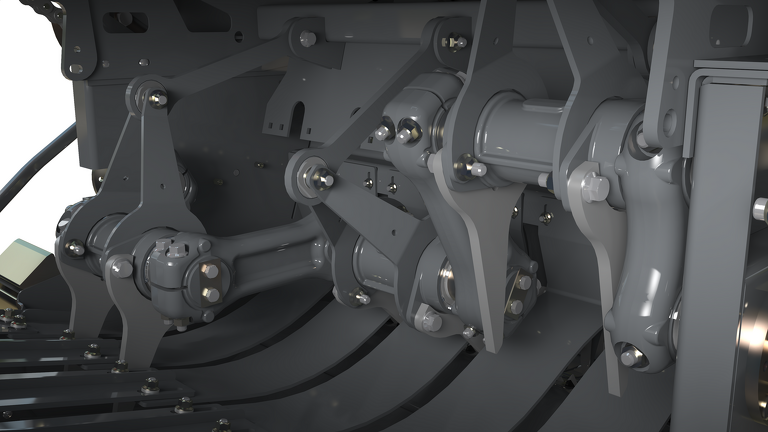

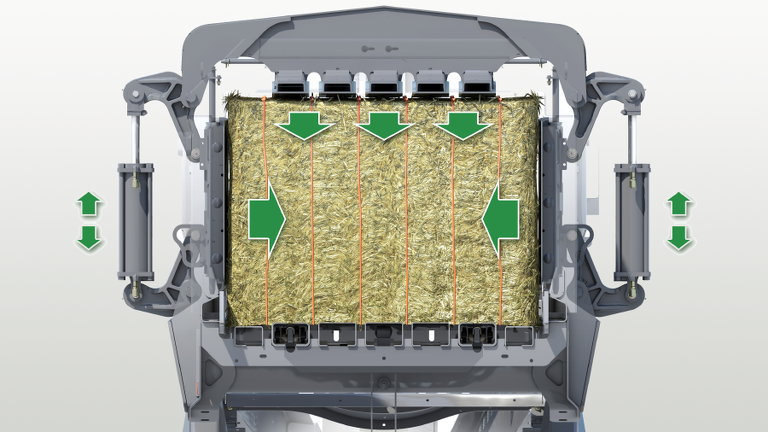

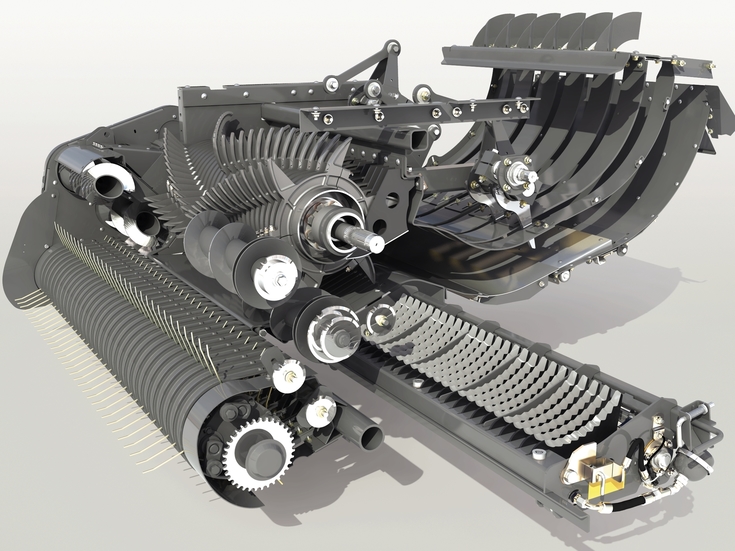

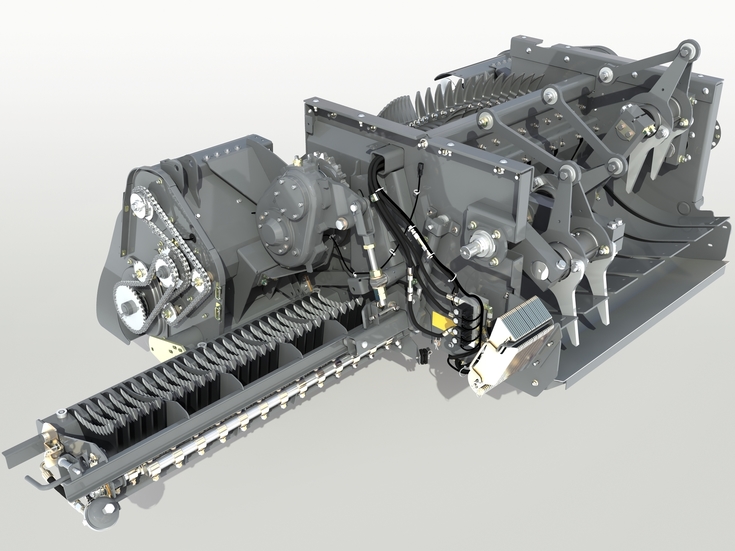

Fendt has equipped its square balers with a very efficient and robust main gearbox to ensure the best operational security. Furthermore, the new v-shaped rotor cutter with 3 rows of tines guarantees a high throughput rate and perfect quality of cut. The unique baling system, with a mechanically controlled pre-compression chamber, guarantees uniformly shaped, highly dense bales – one like the other. The main bale chamber is responsible for solid compression.

Precompression chamber

Packer

bale chamber flaps

Charge holding fingers

Sensor flap

Baler

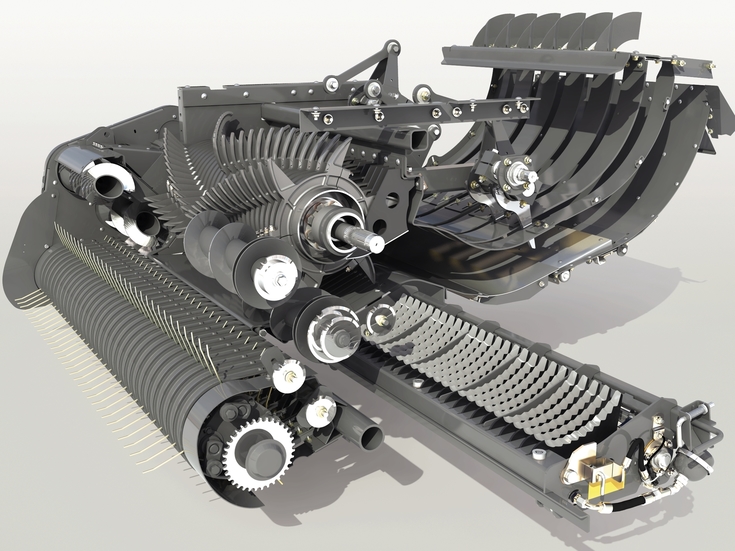

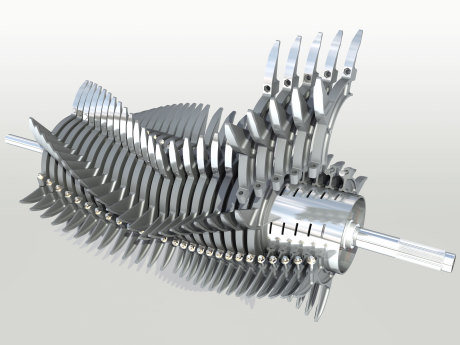

The heart of the table: the rotor cutter

The heart of the table: the rotor cutter

The v-shaped arrangement of the rotor tines sets up the crop for a perfect cut – with a uniform, efficient cutting process and no load peaks. The new rotor cutter runs at a speed of 120 rpm and has 3 rotor tines per rotor ring. This ensures a high cutting frequency and increases the throughput rate, resulting in lower fuel consumption. The rotor tines are hardened with carbon and especially robust and durable.

The heart of the table: the rotor cutter

The v-shaped arrangement of the rotor tines sets up the crop for a perfect cut – with a uniform, efficient cutting process and no load peaks. The new rotor cutter runs at a speed of 120 rpm and has 3 rotor tines per rotor ring. This ensures a high cutting frequency and increases the throughput rate, resulting in lower fuel consumption. The rotor tines are hardened with carbon and especially robust and durable.

V-shaped rotor cutter with bolted rotor tine segments. A high speed of 120 rpm means a high cutting frequency for enhanced threshing performance with the best quality of cut.

The lowered knife drawer can be pulled out on the left side of the machine to change knives.

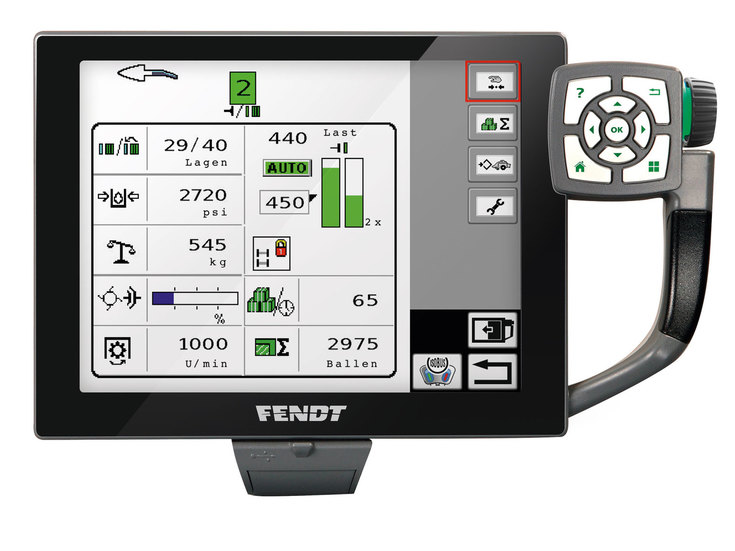

The perfect operating interface

A control terminal should be one thing most of all – user-friendly. It is optimally integrated in the overall operating concept; you can operate your Fendt square baler via the Fendt Varioterminal. The straightforward menu has a logical structure and is therefore extremely easy to use. The menu for the square baler is automatically loaded via ISOBUS technology, so you can begin working immediately.

Everything under control with the Varioterminal

ust as in the Varioterminal, the baler menu can be viewed by the operator in full screen or partial screen modes. The target values for the plunger load can be set there. The machine then controls the bale chamber flaps automatically. An electric bale length adjustment facility is available as an option. Operators set the desired length for the bale and the automated function triggers the knotting procedure when the bale has reached the target length. Electric adjustment permits fast changes between different lengths, which is of particular interest for contract work. Using the terminal, operators can also set the lubrication interval for the knotter lubrication system as well as create jobs, read out the number of bales and operate the bale chamber manually.

An electric bale scale is available as an option. It tells the operator in real-time, if the desired bale weight has been reached. The Varioterminal 9 with touchscreen is the standard-equipped terminal. If no ISOBUS-capable tractor is available or operators prefer an additional terminal, they can fall back to the Varioterminal 9 at any time. All functions are also available in this terminal.

Ready to go with the ISOBUS

The Fendt square balers are compatible with the ISOBUS as standard. This allows the baler to be operated directly through the Varioterminal or a terminal of an ISOBUS-compliant tractor. You only need to connect one cable and your familiar user interface already appears on the monitor in the cab. Additional control units can further simplify machine operation, depending on the tractor.

The Fendt square balers are compatible with the ISOBUS as standard. This allows the baler to be operated directly through the Varioterminal or a terminal of an ISOBUS-compliant tractor. You only need to connect one cable and your familiar user interface already appears on the monitor in the cab. Additional control units can further simplify machine operation, depending on the tractor.

Thanks to ISOBUS compatibility, the machine can be conveniently controlled in the Fendt Varioterminal.

The Varioterminal 9 is fitted as standard. If the tractor is not ISOBUS-compliant or operators desire a separate terminal, it is possible to fall back to the Varioterminal 9 at any time.