Perfect down to the last stalk: The Fendt Slicer disc mowers

Perfect forage can only be harvested by perfect machines. Fendt Slicer disc mowers give you a perfect, consistent cutting height – for impressive mowing results. You'll be thrilled with the feed quality.

Power par excellence – we combine a Slicer front mowing unit and a butterfly mowing combo at the rear; it's an unbeatable mowing experience that's all down to a whole host of clever details.

Nothing is more versatile. Mowers to meet your every need.

Your practical requirements are what makes a Fendt Slicer disc mower. Intelligent lightweight design and maximum service life go hand in hand at Fendt, ensuring ease-of-use and low fuel consumption. Innovative drives reduce fuel demands.

Choose from a variety of front and rear mowers of different working widths and specific accessory adaptations - the right combination for all terrains and harvesting conditions.

The Fendt Streamline cutter bar - better cutting

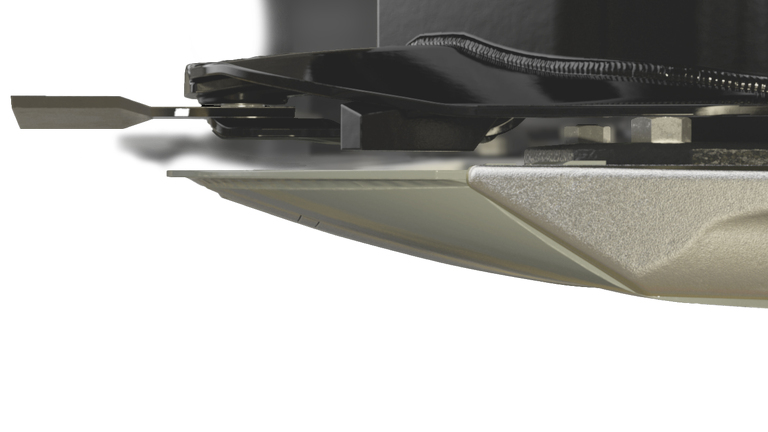

The Fendt Streamline large-disc cutter bar impresses with its wide range of applications and high efficiency under all conditions. Its remarkable gliding properties, ease of pulling and powerful crop flow support economical mowing, high forage quality and protection of the turf in equal measure.

Sustainable, safe and effective

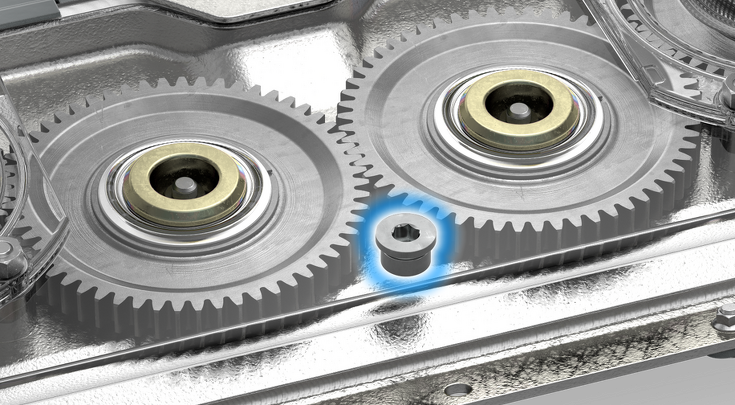

Fendt mowers with the new spur gear cutter bar can be operated with a reduced PTO speed of 850 rpm under good weather and crop conditions. The complete drive train is designed to achieve optimum power utilisation depending on the requirements. Fuel-saving mowing is thus possible with consistent cutting and forage quality. The overload protection and the integrated freewheel in the gearbox prevent expensive damage to the machine in emergencies. The integration into the lightweight and dimensionally stable support frame is designed to create a large forage swath and plenty of space for tine or roller conditioners.

Alles fließt

Perfectly stable

Direct drive

Top geared

Powerful in unison

In great shape

| Working width | Number of cutting discs | |

| Slicer 310 FQ/FQ KC/FQ RC | 3,10 m | 6 |

| Slicer 360 FQ/FQ KC/FQ RC | 3,60 m | 7 |

| Slicer 3160 TLX/TLXKC/TLXRC | 3,10 m | 6 |

| Slicer 3670 TLX/TLXKC/TLXRC | 3,60 m | 7 |

| Slicer 860 /KC/RC | 8,30 / 8,60 m | 2 x 6 |

| Slicer 960 | 9,30 / 9,60 m | 2 x 7 |

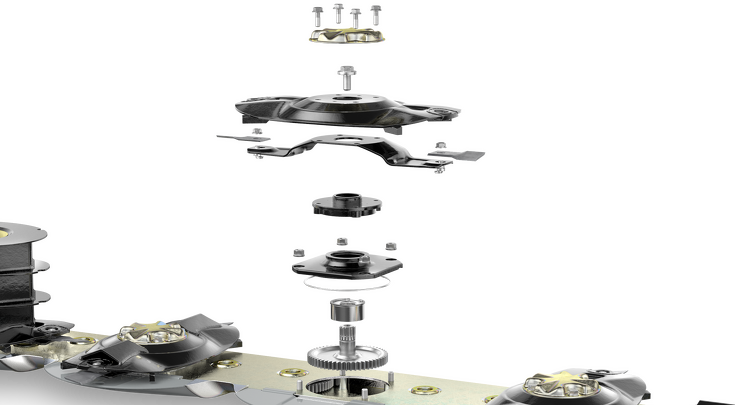

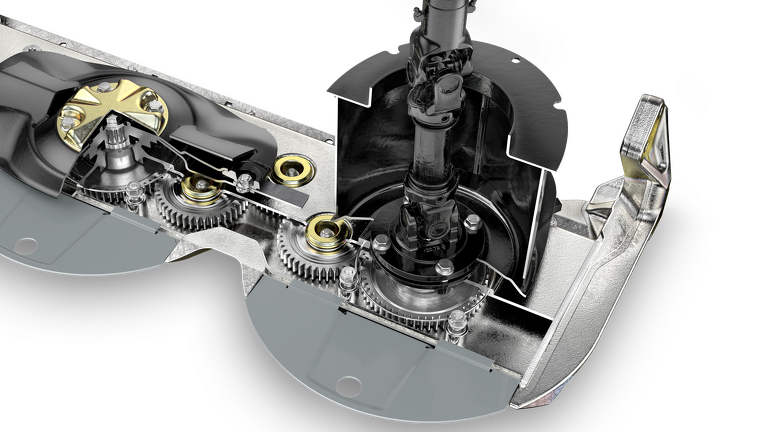

The compact angle drive - traditionally strong

The heart of the compact angle cutter bar is the continuous hexagonal shaft that drives the individual angle drives and on whose flanges the mower discs are mounted. The result is a uniform power output that guarantees the highest cutting quality. The hexagonal shaft and the compact angle drives run in a lifetime oil filling for optimum lubrication in every situation. A predetermined breaking point on the hexagonal shaft means that work can be continued quickly by replacing the shaft in the event of damage. Every Fendt Slicer disc mower with compact angle drive has multiple overload protections. All models are equipped with either a V-belt drive or a slipping clutch in the drive train and also have an overload protection on each mower unit.

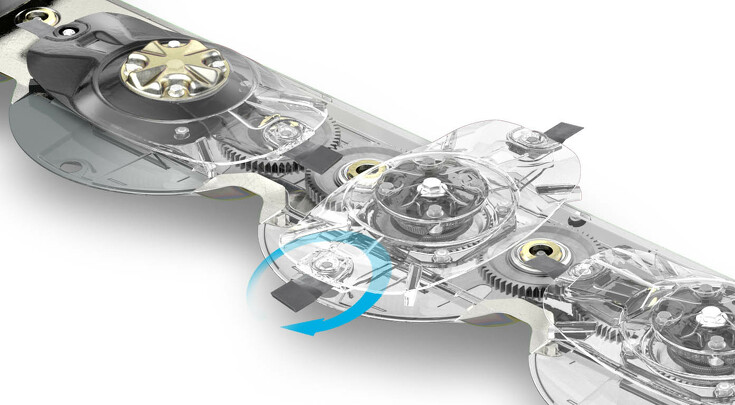

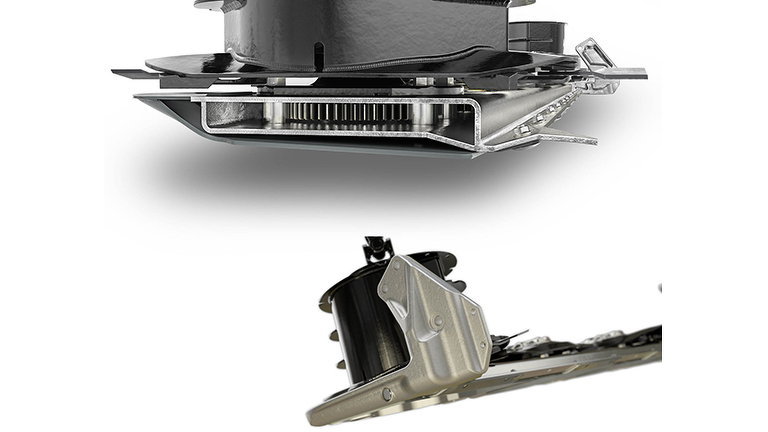

The spur gear drive with small pulleys - the lightweight

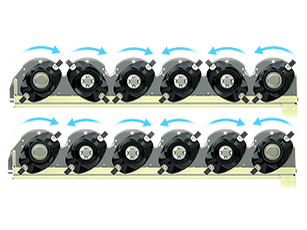

These Fendt Slicer disc mowers with front drive feature a lightweight design, which reduces ground pressure. The cutter bars are very flat, which gives an excellent cutting pattern and optimum forage flow. The drive is provided by an elastic V-belt drive, which drives the first mower disc with the spur gear from above via a cardan shaft. Further power transmission is from spur gear to spur gear, ensuring uniform power delivery to all mower discs. Working widths of over 3.00 m can also be achieved with smaller tractors.

Always the right solution

The Fendt Slicer disc mowers offer different cutter bars for different applications. The innovative Fendt large-disc spur gear cutter bar has a robust and flat design. It impresses with a high degree of efficiency, optimum crop flow and great flexibility of use. The indirectly driven, stable compact angle cutter bar is characterised by durability and reliability even in difficult conditions. Fendt Slicer disc mowers with the very light standard spur gear cutter bar combine a weight-reduced design with easy handling.

All disc mowers can be equipped with the convenient Comfort Change quick-change blade system. The lockable special tool makes changing blades child's play. The blade locks automatically and is reliably secured. Comfort Change reduces downtime, saving money and valuable time in the tight harvest window.

Maximum soil protection, minimum forage contamination

On the Fendt Slicer rear mowers with centre suspension, the mower combinations and the Slicer FQ front mower, the patented hydropneumatic cutter bar relief "TurboLift" ensures a floating cut. The TurboLift system constantly ensures the optimum ground pressure during the mowing process and can be quickly and continuously adjusted to the conditions, even while driving. This increases turf protection and forage quality. Especially in damp and wet areas, the crude ash content in the feed is significantly reduced.

| Working width | Attachment | |

| Slicer 860 /KC/RC | 8,30 / 8,60 m | Rear mower combination |

| Slicer 960 | 9,30 / 9,60 m | Rear mower combination |

| Slicer 3160 TLX/TLXKC/TLXRC | 3,10 m | Rear attachment |

| Slicer 3670 TLX/TLXKC/TLXRC | 3,60 m | Rear attachment |

| Slicer 310 FQ/FQ KC/FQ RC | 3,10 m | Front towing bracket |

| Slicer 360 FQ/FQ KC/FQ RC | 3,60 m | Front towing bracket |

Infinitely adjustable

Before mowing, set the relief pressure you want in the TurboLift system. The mower pressure can then be relieved further at any time on the go, and the preselected pressure restored. This allows it to react extremely flexibly to changing conditions. On headlands, the system always calibrates itself. Alongside perfect forage quality, TurboLift means that little tractive power is required and also means significant fuel savings. At the push of a button on the TurboLift valve block, you can completely relieve the cutting unit pressure and park it safely and easily.

Experience in Hay

A century of silage expertise Tradition, innovation and passion – that’s the recipe for success of the silage centre of expertise in Feucht.