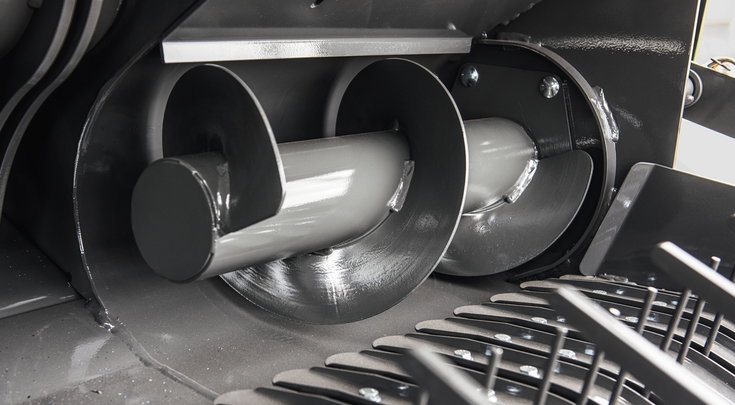

The highest possible output can only be attained if you start with a perfect forage pick-up system. When it comes to Fendt round balers, this is guaranteed with a high-performance cam track-free pick-up with a width of 2.25 m. The special geometry of the segment sheets and ideal angle of the extra-long tines make it easier to control the cam tracks. Consequently, the pick-up contains fewer moving and wearing parts, runs smoother and is easier to maintain.

A pick-up that misses nothing.

Pick-up for maximum output

Close to the rotor

Thanks to the very compact design, the pick-up is situated close to the rotor. This simplifies the process in which the forage is transferred from the pick-up to the rotor and aids the crop flow. The benefits of this can be seen very clearly when working with short and brittle material, i.e. the material is conveyed to the bale chamber far more gently and efficiently. The optimal crop flow enables you to compress one perfect bale after another and achieve a high hourly output.

Five tine bars:

The absence of cam shafts and followers frees up additional space. This is why the pick-up now has five tine bars. For the best forage pick-up, the tine gap was set to an extremely low 64 mm. This ensures that no unused stalks are left behind in the field. Two lateral feed screws are also factory installed.

The tines are decisive:

The tines are the basic components of the pick-up. Its special work angle collects the forage in a manner that ensures that the sward remains protected. The 5.6 mm diameter ensures an enormous service life and the tines are very flexible with the large wrapping. A robust tine attachment prevents the tines from breaking off, as the tension is evenly distributed.

Cut your forage as per your requirements.

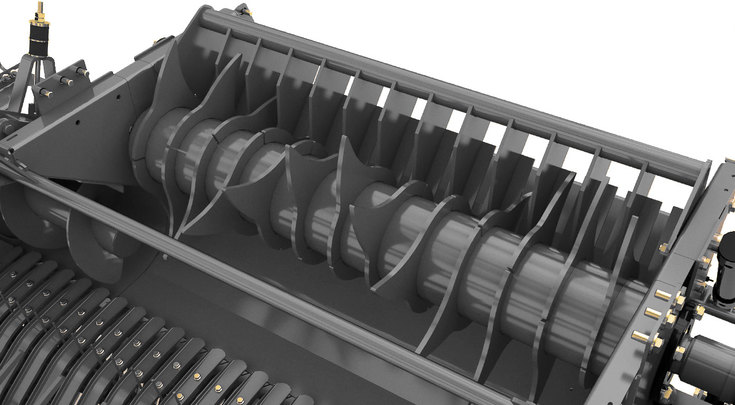

Perfect rotors for high output

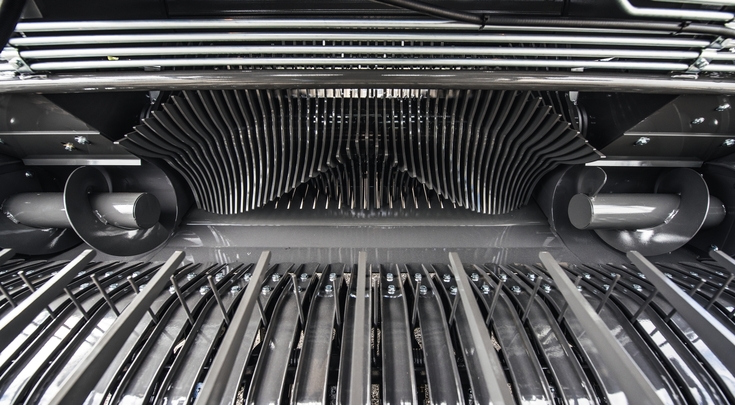

Fendt's three round baler models feature four different rotors, which make sure that the system is compatible with the task at hand. The rotor speed is 134 rpm. The v-shaped arrangement of the conveying fingers ensures that the bale chamber is filled up evenly. Depending on the performance class, the compactors are equipped with either a rigidly fitted floor or a Hydroflex floor.

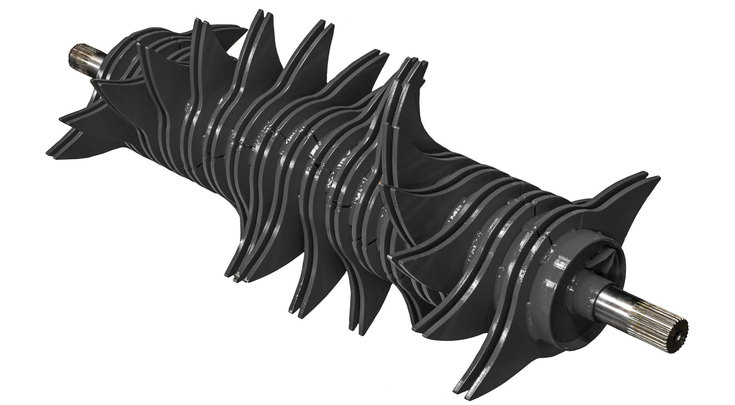

Full flexibility: XtraCut 13 & XtraCut 17

The Fendt 130 F Xtra round baler uses either the XtraCut 13 or XtraCut 17 rotor. These two-finger rotors have been designed for the highest possible output and longest possible service life. With the XtraCut13, you can decide whether or not you want to use a cutting table. The XtraCut 17 rotor achieves a potential cutting length of 67.5 mm and engages groups of 0, 8, 9 or 17 knives. Dummy knives that make it possible to work without using knives are supplied with all round balers with cutting table, therefore preventing crumbling losses and protecting the cutting table from wear and tear.

Quality of the cut for discerning producers: XtraCut 25:

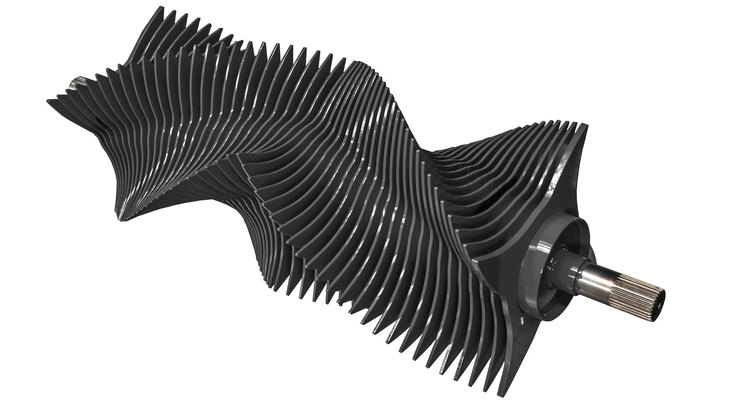

When it comes to output and the quality of cut, the Fendt XtraCut 25 rotor in the 130 F Xtra scores highest in Fendt's line-up of round balers: The v-shaped four-star rotor is made for extensive harvest volumes. With very thin layers, it feeds the bale chamber with a cutting length of 45 mm, for high-density bales. Hydroflex is always factory-installed in this case as well. There is a hydraulic knife group containing 0, 12, 13 or 25 knives.

Cutting with the longest knife:

Fendt's XtraCut models that are equipped with cutting tables feature the longest knife in the market, for the best possible quality of cut. There is a hydropneumatic knife protection facility featuring two pressure accumulators, whose preload is 40 bar. This increases the service life of the round balers. If the knives can no longer move into the operating position, e.g. due to dirt, a pressure of 180 bar can be applied temporarily. The elaborate task of scraping the knife slits gives way to the simple touch of a button on the control unit.

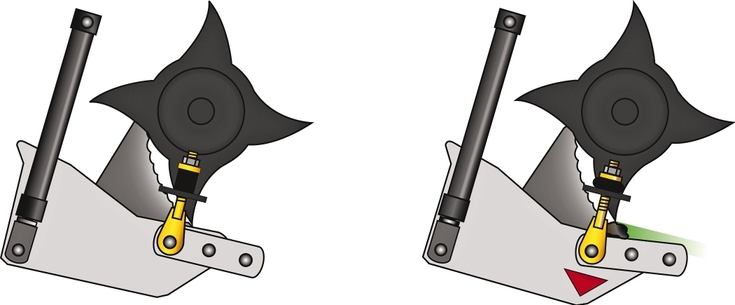

Consistently smooth supply with HydroflexControl.

Spring-mounted, lowerable

The first component is the permanent suspension of the cutting floor, known as 'Flex'. A spring can be used to gently swing the cutting floor upwards and downwards. This ensures that the cutting floor can respond to fluctuating forage quantities. 'Hydro' is the second component of the system. This component involves two hydraulic cylinders, which make it possible to hydraulically open the floor from the cab at the touch of a button, in order to either eliminate blockages or change knives. HydroflexControl enables you to move the machine over a long period of time hand in hand with high output.

Nonstop baling:

Even in difficult conditions, blockages are almost completely avoided with the feed mechanism. When the output keeps rising, the intelligent cutting floor found in Fendt round balers prevents blockages through its freedom of movement. This effective anti-blockage system allows stress-free compaction with high daily outputs.

Two parts, singular comfort:

In order to be able to make perfect use of the round baler throughout the day, blockages must be prevented before they occur. The HydroflexControl system in Fendt round balers ensures that this happens. 80% of blockages are reliably and effectively prevented through the interaction between two components, for high daily output.

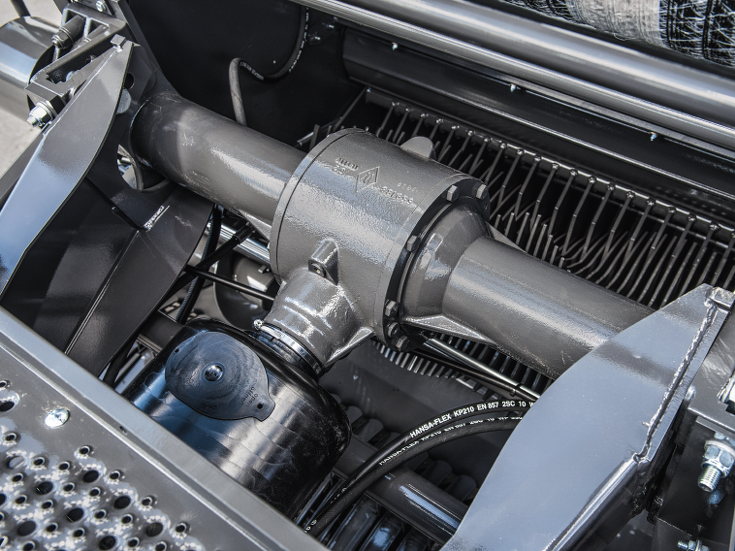

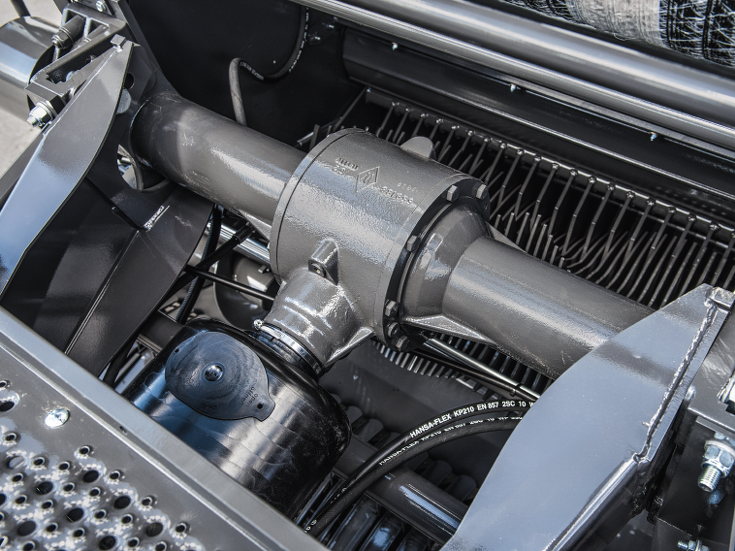

The power drive which gets everything started.

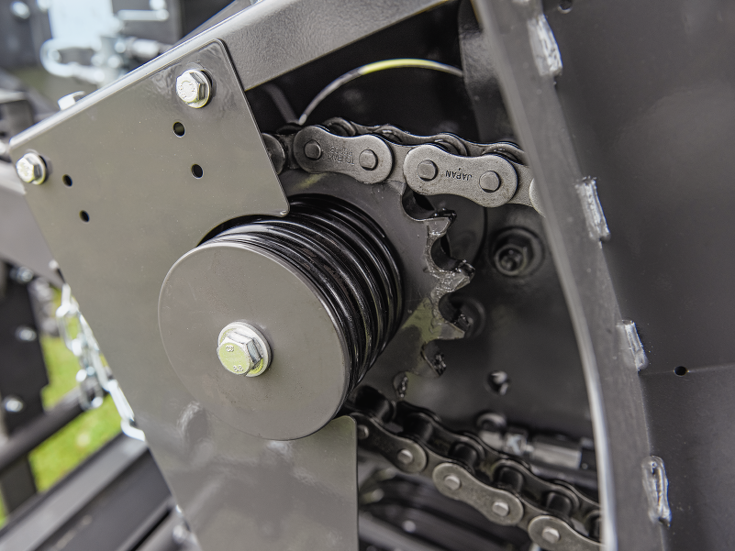

Clear structure

The right side of the Fendt round balers houses the rotor drive, which is associated with a duplex chain. The 18 PowerGrip rollers are driven on the left-hand side. The chamber drive is divided into two tracks. Therefore, only every second roller is driven by a track, and less force is exerted onto the individual components, which leads to less wear and abrasion. The tracks are manufactured by Tsubaki; they are top-quality, durable items. The free wheel sprocket guarantees safety: If the transmission shaft is stopped or the rotor abruptly comes to a standstill because of a blockage, the free wheel facilitates a gradual deceleration of the bale rotation. This ensures that the main drive components are reliably protected against damage caused by abrupt stress.

Very simple maintenance:

Fendt round balers require very little maintenance time. The light swing-up side flaps make it very easy to reach the maintenance points. The automatic track lubrication system - which is driven via the baling rollers - always reliably applies the desired quantity of oil to the tracks. This extends the lifetime and guarantees smooth motion. The bearings of the PowerGrip rollers are quickly and easily lubricated with the help of a central lubricating bar. Stop wasting time searching for the lubrication points.

More power with Powersplit:

All models are fitted with a Power Split gearbox. The Power Split gearbox is a split-drive concept that distributes the required power perfectly evenly to the rotor and chamber drive. Again, the input speed is 540 rpm. In models without cutting floor, a 1650 Nm shear pin clutch guarantees safety. In the models with cutting floor, a cam and free wheel clutch also protects the drive train with 1950 Nm.

The Power Split gearbox runs at a PTO speed of 540 rpm.

The Power Split gearbox runs at a PTO speed of 540 rpm.

The chamber drive is divided into and powered by two tracks.

The free wheel sprocket ensures that the drive train is protected against damage in the event of a rotor blockage.

Fendt round balers only use Tsubaki chains.

The 50 mm bearings on the rollers are designed for extremely high loads.